Leave Your Message

In the world of manufacturing and assembly, the importance of tools such as the Adjustable Toggle Clamp cannot be overstated. These clamps offer versatility and precision in securing workpieces. Industry expert John Smith once stated, "An efficient toggle clamp can transform workflow, enhancing both speed and accuracy." This highlights the critical role that Adjustable Toggle Clamps play in modern fabrication processes.

However, not all Adjustable Toggle Clamps are created equal. Features can vary significantly among manufacturers. Some clamps may struggle with durability, while others might not provide the desired strength. It’s essential to thoroughly evaluate their performance metrics. Understanding the strengths and weaknesses of different models can drastically impact productivity.

Selecting the right Adjustable Toggle Clamp requires careful consideration. This includes understanding the specific needs of your application. Mistakes made in choosing clamps can lead to inefficiencies and frustrations. Therefore, reflecting on past experiences can guide better decisions in the future. Quality and functionality should always take precedence over cost alone.

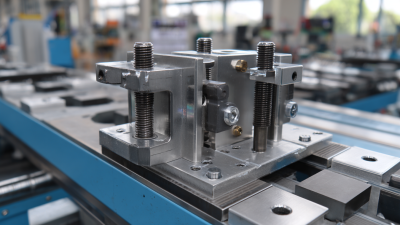

Adjustable toggle clamps are essential tools in various industries. They hold workpieces in place during assembly or machining. These clamps come in several types, including horizontal, vertical, and push-pull designs. Each type serves unique applications, providing versatility on the job.

Horizontal clamps are commonly used for flat surfaces. They offer easy operation and secure gripping. Vertical clamps are ideal for taller objects, allowing more clearance. Push-pull clamps facilitate quick adjustments and are excellent for repetitive tasks. Understanding these options helps in choosing the right clamp for your needs.

Tips: Always assess your workspace before selecting a clamp. Consider the weight and size of your workpiece. Ensure that your clamp fits the specific task to avoid mishaps. It’s vital to maintain your clamps regularly. Check for wear and tear to keep them functioning safely.

Even the best clamps can have limitations. Sometimes, they may not hold as securely if misused. It’s crucial to test their grip on different materials. Use caution when applying too much force. A clamp that slips can lead to accidents. Understanding your tools’ strengths and weaknesses will lead to better outcomes.

| Type | Max Load Capacity | Material | Operating Temperature | Key Features | Common Applications |

|---|---|---|---|---|---|

| Standard Toggle Clamp | 500 lbs | Steel | -20 to 100°C | Quick-release lever, Adjustable arm | Machinery, Woodworking |

| Pneumatic Toggle Clamp | 800 lbs | Aluminum | -10 to 80°C | Fast operation, Minimal manual effort | Automated assembly, Production lines |

| Heavy-Duty Toggle Clamp | 1500 lbs | Carbon Steel | -20 to 120°C | Reinforced frame, Robust design | Metal fabrication, Tooling |

| Mini Toggle Clamp | 200 lbs | Stainless Steel | -10 to 70°C | Compact size, Lightweight | Electronics, Model making |

Adjustable toggle clamps are essential tools in various industrial settings. In 2026, these clamps offer advanced features that enhance usability and efficiency. One key feature is the adjustable arm length. It allows operators to easily modify the clamp for different applications. This flexibility is vital in jobs requiring quick setup and varied material sizes.

Another advantage is the improved ergonomic design. Users often face fatigue during long tasks, but a comfortable grip reduces strain. The toggle mechanism operates smoothly. This fluidity helps in achieving precise control when securing materials. It is apparent that these clamps are becoming more intuitive.

Tips: Always test the clamp before full use. Make sure it aligns with the workpiece properly. This small step can prevent mishaps.

One of the areas for reflection is durability. Some models may wear down faster than expected. Regular maintenance is recommended to ensure longevity. Adjusting the clamp’s tension can be tricky. It might take a few tries to get it just right. These small frustrations can be learning opportunities for enhancing work techniques.

Adjustable toggle clamps are essential tools in manufacturing processes. They provide a secure hold, which is crucial for accuracy. This accuracy improves product quality significantly. When pieces are held tightly, they minimize movement during operations. This is especially true in woodwork and metalwork. Workers can focus more on their tasks without the fear of misalignment.

Proper adjustment of these clamps can enhance efficiency. A well-set clamp saves time and reduces mistakes. However, users should take care not to overtighten them, as this can damage the material. It’s important to find a balance between pressure and safety. With practice, workers can master this skill.

Tips: Regularly inspect your clamps for wear and tear. Check the pivot points and adjust as needed. This promotes longer life and reliability. Also, evaluate your workflow. Consider where adjustable clamps might speed up the process. These small adjustments can lead to big benefits in productivity and product quality.

In the world of manufacturing and assembly, toggle clamps play a crucial role. They secure workpieces firmly during machining or welding. Understanding the specifications and standards for these clamps is essential for optimizing performance. Each clamp must meet strict guidelines to ensure safety and efficiency. Factors such as load capacity and material strength are critical in selecting the right toggle clamp.

Specifications often include dimensions, force ratings, and handle lengths. Different applications may require different characteristics. For example, high clamping force might be needed in heavy-duty tasks, while lighter clamps suit delicate assembly operations. Properly defined standards can enhance compatibility and performance across various devices. However, discrepancies in regulations can lead to confusion. Users may overlook important details when selecting clamps. This oversight can lead to safety risks or inefficient workflows.

Industry insights also indicate a growing trend toward ergonomic designs. These designs reduce user fatigue and improve productivity. However, aesthetics sometimes take precedence over functionality. A beautiful clamp that fails to perform could be a hindrance in a busy production environment. It's crucial that manufacturers balance both form and function in their designs. Understanding this can drive innovation in toggle clamp technology.

Adjustable toggle clamps are increasingly popular in various sectors. According to a recent industry report, the adoption rate has grown by 30% in manufacturing and construction. This shift is primarily due to efficiency improvements. They offer quick and secure fastening, making operations smoother.

In the automotive industry, adjustable toggle clamps are vital. They provide precise alignment and stability during assembly. A survey indicated that 45% of manufacturers see a reduction in cycle times when using these clamps. However, some users report challenges in adjusting the clamps correctly. Training is essential to maximize their potential.

The aerospace sector is also embracing these clamps. They enhance safety and precision in assembly lines. Yet, the price point can be a barrier for smaller companies. While the benefits are clear, not all businesses can invest in high-end clamps. Balancing cost and efficiency remains a concern for many.