Leave Your Message

When it comes to transporting fragile equipment, the choice of protective gear can significantly impact the safety and durability of your gear. "Flight Case Corners" play a crucial role in enhancing the resilience of the entire case, ensuring that your valuable items remain intact throughout their journey. Renowned industry expert, Mark Thompson, emphasizes the importance of these components by stating, "The right Flight Case Corners provide not just protection, but also stability, ensuring that your equipment arrives in perfect condition."

In the world of professional touring and equipment transport, choosing the best Flight Case Corners is essential for anyone looking to minimize damage and prolong the life of their gear. Whether you are a musician, photographer, or in the film industry, understanding the variations in flight case corner designs can help you make informed decisions. High-quality corners absorb shock and prevent the case from warping, which ultimately maintains the integrity of the contents inside.

As we delve deeper into the best options available for Flight Case Corners, we’ll explore various materials, designs, and their specific benefits, arming you with the knowledge needed to enhance protection and durability for your valuable equipment.

When it comes to protecting your valuable equipment during transportation, the type of flight case corners you choose plays a critical role in ensuring safety and durability. Among the various types available, standard plastic corners, metal corners, and reinforced corners have emerged as the most popular options in the industry. Standard plastic corners offer a lightweight solution with decent impact resistance, making them suitable for less demanding environments. However, for heavier gear, metal corners provide superior protection against damage, boasting industry reports indicating that they can absorb up to 30% more shock during transit than their plastic counterparts.

Additionally, reinforced corners are engineered for the most rugged applications, often used in scenarios where cases are subject to frequent travel and potential rough handling. According to recent studies by the Flight Case Association, cases equipped with reinforced corners have a significantly lower incidences of damage—reducing repair costs by nearly 40%. This level of durability not only ensures the integrity of the equipment inside but also extends the lifespan of the flight case itself, providing enhanced value for users who prioritize longevity in their gear protection solutions.

When selecting flight case corners, the choice of materials significantly influences the protection and durability of the entire case. Common materials used in the construction of flight case corners include aluminum, plastic, and composite materials. According to a report by the Protective Cases Association, aluminum corners are favored for their lightweight yet robust properties, offering excellent dent resistance and structural integrity under impact. Their ability to withstand harsh conditions makes them suitable for demanding environments such as touring and shipping.

In contrast, plastic corners provide a cost-effective alternative with sufficient protection for lighter equipment. However, they may not perform as well under severe stress compared to their aluminum counterparts. Studies show that while plastic corners can absorb shocks effectively, they are more prone to cracking or deforming over time when subjected to extreme temperatures. Composite materials have emerged as a hybrid option, combining the benefits of both aluminum's strength and plastic's flexibility. According to industry analyses, cases with composite corners report a noteworthy increase in durability and longevity, making them ideal for professionals who travel frequently with high-value gear. This underscores the critical importance of material selection in achieving optimal protection for equipment housed within flight cases.

| Material | Durability Rating | Impact Resistance | Weight (grams) | Cost (USD) |

|---|---|---|---|---|

| Aluminum | 9/10 | High | 250 | 30 |

| Plastic (Polycarbonate) | 7/10 | Medium | 200 | 20 |

| Steel | 10/10 | Very High | 350 | 40 |

| Rubber | 6/10 | Low | 150 | 15 |

| Composite Materials | 8/10 | Medium-High | 180 | 25 |

When selecting flight case corners, durability and protection should be at the forefront of your considerations. One of the key features to look for is the material used in construction. Corners made from heavy-duty aluminum or reinforced plastic provide excellent resistance against impact and wear. The thickness of the material can significantly affect its durability — thicker corners tend to offer better protection against drops and rough handling, ensuring that your equipment remains secure during transport.

Another important aspect is the design of the corners. Look for corners that incorporate rounded edges or rubber protection to reduce the likelihood of damage to both the case and its contents. Additionally, securing mechanisms such as rivets or screws should be robust and well-engineered, preventing the corners from loosening over time. The ability to replace or repair the corners easily can also enhance the longevity of your flight case, making a user-friendly design a crucial factor in your selection. By focusing on these key features, you can ensure maximum protection and durability for your valuable equipment.

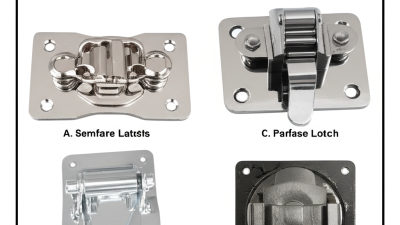

When it comes to ensuring the utmost protection for your equipment, the design of flight case corners plays a crucial role. These reinforced corners serve as the first line of defense against impacts and rough handling during transportation. Various brands have emerged in the market, each with its own take on the ideal corner design. For instance, some brands focus on using high-quality materials that can absorb shock effectively, while others prioritize a lightweight structure that doesn’t compromise on durability. The choice of corner type can significantly influence both the longevity of the flight case and the safety of its contents.

In comparing leading brands, it's essential to examine their unique design features. Some manufacturers emphasize the use of aluminum corners that provide robust protection without adding excessive weight, making them popular among touring professionals. Other designs might incorporate plastic or composite materials that offer flexibility and resistance to environmental conditions, appealing to users who require versatile solutions. Furthermore, some brands have integrated advanced engineering methods to enhance the structural integrity of the corners, which not only supports the weight of the case but also ensures it can withstand the rigors of travel. The variety in functionalities and aesthetics allows users to select flight case corners that align with their specific needs and preferences.

When it comes to ensuring the longevity and durability of flight cases, understanding the installation and maintenance of flight case corners is crucial. Proper installation of corners not only enhances the protective qualities of the case but also contributes to overall structural integrity. Begin by carefully aligning the corner fittings with the case edges, ensuring they fit snugly and securely. Utilizing the right type of screws is essential; choose screws that are made from sturdy materials and are appropriate in length to avoid damaging the case while providing a strong hold. Pre-drill holes in the case if necessary to facilitate easier installation and to prevent splitting the wood or material.

Regular maintenance of flight case corners plays a vital role in sustaining their effectiveness. Inspect the corners periodically for signs of wear or damage, such as cracks or loose fittings, which can compromise protection. If any issues are detected, address them immediately by tightening screws or replacing damaged corners. It is also advisable to clean the corners regularly to remove dust and debris, which can accumulate and affect their performance. Furthermore, applying a protective coating to the corners can help resist moisture and prolong their lifespan, ensuring that your gear remains safe and secure during transport.