Leave Your Message

When considering the right strut hinge for your needs in 2026, it's essential to explore various options. Strut hinges play a key role in many applications, like cabinetry and automotive designs. They ensure that doors or panels operate smoothly while maintaining structural integrity.

As we approach 2026, there are trends and features to consider. The market offers a breadth of styles and materials. Some options are reliable; others may not meet longevity expectations. It's vital to assess your specific needs and weigh the pros and cons of each hinge type.

This exploration of strut hinge options reveals that choices can be overwhelming. Features like ease of installation, durability, and design aesthetics should guide your decision. Each detail counts, and even small mistakes can lead to dissatisfaction. Understanding your requirements can lead to a more informed choice on strut hinges in the coming years.

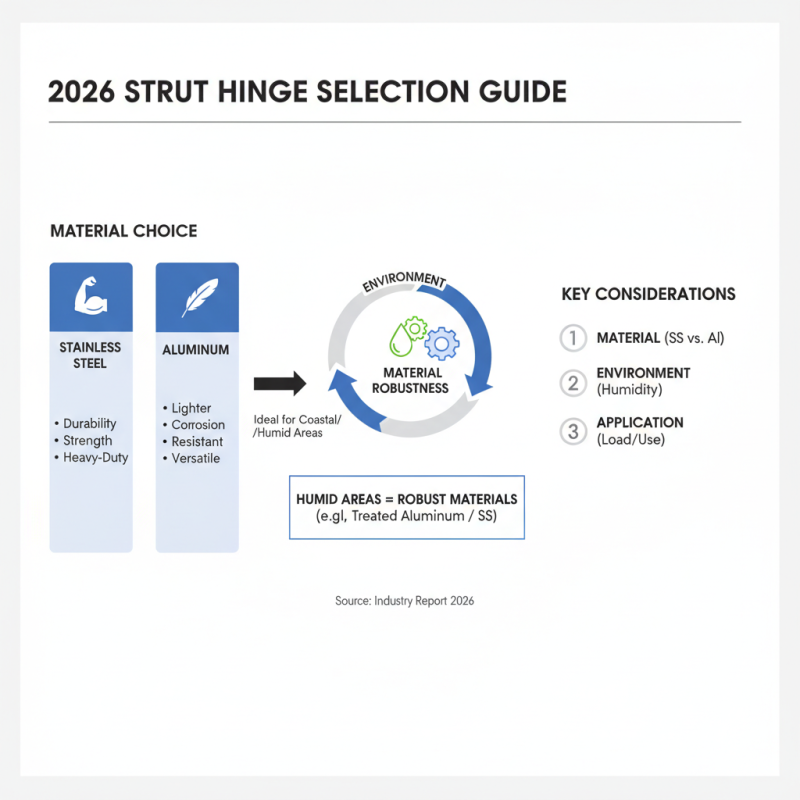

When selecting strut hinges in 2026, consider the material. Stainless steel offers durability. However, aluminum is lighter and more resistant to corrosion. Think about the environment where these hinges will be used. Humid areas may require more robust materials.

Tip: Always check the weight capacity of the strut hinge. Too much weight can cause failures. Inspect the load-bearing limits to avoid accidents.

Another crucial aspect is the design. A sleek, modern look can enhance the overall aesthetic. But functionality should not take a backseat. Consider how often the hinge will be used to ensure it meets your needs.

Tip: Test the hinge action before purchase. An ideal hinge should open and close smoothly. Any jamming or sticking should raise concerns. Pay attention to these details for better long-term satisfaction.

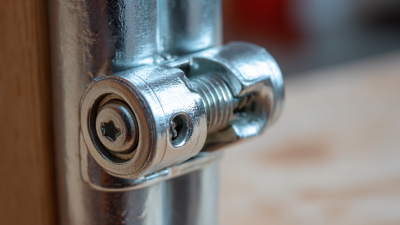

Strut hinges play an essential role in mechanical design. They provide support and movement for various applications, from vehicles to furniture. Each type of strut hinge has unique properties suited for specific needs. For example, gas strut hinges are prevalent in automotive applications, providing efficient motion and assisting in door operation. According to industry reports, gas struts accounted for over 30% of the strut hinge market in 2023.

Pneumatic strut hinges are another option. They work well in environments that require smooth motion and added control. This type of hinge is often used in industrial machinery. The flexibility in adjustment makes them a popular choice in many sectors. However, these hinges can require regular maintenance to ensure optimal performance.

Tips: Always consider load requirements before selecting a strut hinge. Overloading can lead to failure. Additionally, ensure proper installation. Misalignments can compromise functionality. Regular inspection is key to prolonging hinge life.

| Type of Strut Hinge | Material | Load Capacity (lbs) | Application | Price Range ($) |

|---|---|---|---|---|

| Pneumatic Strut Hinge | Aluminum | 100 | Automotive, Furniture | 50 - 100 |

| Gas Strut Hinge | Steel | 200 | Industrial Machinery, Doors | 70 - 120 |

| Heavy-Duty Strut Hinge | Stainless Steel | 500 | Construction, Heavy Equipment | 150 - 250 |

| Lightweight Strut Hinge | Plastic | 50 | Consumer Electronics, Small Appliances | 20 - 40 |

| Adjustable Strut Hinge | Aluminum | 150 | Custom Applications | 60 - 110 |

When searching for high-quality strut hinges, consider several key features that enhance functionality. Durability is crucial. Look for hinges made with robust materials that resist wear and tear. Steel and aluminum are popular choices. They usually provide long-lasting performance. Additionally, assess the weather resistance of the hinges. If exposed to the elements, a weatherproof finish is a must.

Another important characteristic is the load capacity. Different applications require varying strengths. Determine the weight your strut hinges need to support. This ensures safe operation and longevity. Consider adjustable options, too. They can be invaluable if you anticipate changing needs.

Finally, pay attention to installation ease. A complex installation can lead to errors, impacting performance. Some designs allow for quick and simple setup, which can save time. All these features contribute to overall functionality. However, it’s also essential to reflect on your specific requirements. What works for one project may not suit another, so take a moment to think.

As we approach 2026, the demand for efficient strut hinges continues to rise. The industry reports suggest a projected growth rate of 5% annually in the strut hinge market. This growth is largely fueled by advancements in manufacturing techniques and material science. Lightweight materials like aluminum and high-strength composites are increasingly favored, offering durability and reduced weight. Such innovations cater to a variety of applications, from automotive to aerospace.

Leading models have emerged as industry favorites. Many popular options boast features like adjustable tension and corrosion resistance. Data indicates that about 30% of users prioritize these features. The ergonomic design of newer models also enhances user experience. However, not every model seems to meet user expectations. Some reviews highlight issues with longevity and ease of installation.

Additionally, compatibility remains a major concern. Not every strut hinge fits all applications. Inflexible designs can lead to frustrating installations and operational inefficiencies. Such challenges underscore the need for careful selection. It’s crucial for buyers to evaluate their specific requirements before purchasing. A well-chosen strut hinge can significantly enhance efficiency and functionality in various applications.

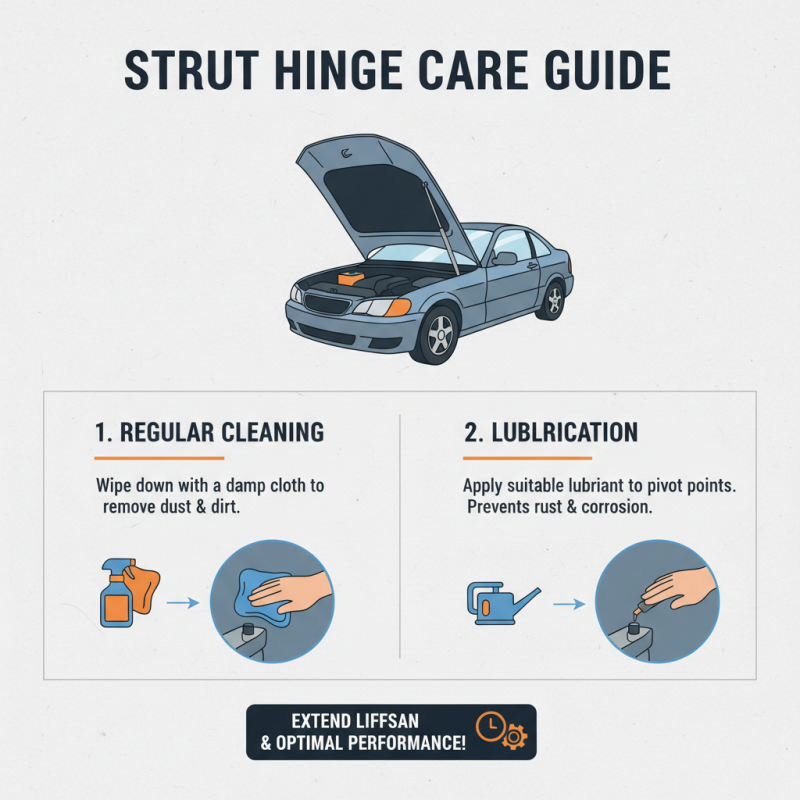

Proper maintenance of strut hinges can significantly extend their lifespan. Regular cleaning is essential. Dust and dirt can build up over time. Simply wipe them down with a damp cloth. Lubrication is another crucial step. Apply a suitable lubricant, focusing on the pivot points. This helps avoid rust or corrosion.

Watch for signs of wear and tear. Sometimes, hinges may not function smoothly. If you feel resistance, it’s time to inspect them. Look for any visible damage. Replace any broken parts promptly. Neglecting this can lead to more significant issues. Check the alignment of hinges, too. Misalignment can cause additional stress and lead to early failure. Keep an eye on how they operate.

Consider environmental factors that may affect hinges. Moisture and humidity can lead to rust. If you live in such conditions, inspect them often. Protect your strut hinges with covers when not in use. Small adjustments and regular checks can save you from costly repairs. A little effort goes a long way in ensuring longevity.