Leave Your Message

When embarking on a home project that requires stability and durability, the importance of selecting the right materials cannot be overstated. Corner Metal Brackets are essential components that provide reinforcement and support in various constructions. As industry expert John Doe once stated, "The right corner bracket can make or break the structural integrity of your project." This underscores the need for careful consideration when choosing Corner Metal Brackets for your specific needs.

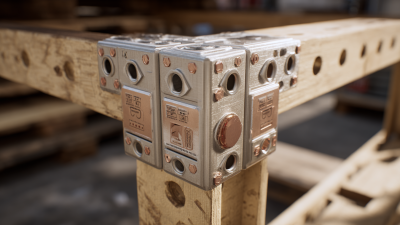

These brackets are diverse in design and function, serving a multitude of applications in furniture building, shelving, and other do-it-yourself projects. Selecting the best options involves understanding the materials, load ratings, and environmental factors that can influence their performance. Whether you're reinforcing a bookshelf or constructing a robust frame, the right Corner Metal Brackets will ensure your project stands the test of time and use.

As you delve into the world of Corner Metal Brackets, consider the project at hand and the specific requirements it entails. From assessing the weight capacities needed to ensuring proper installation techniques, your choices will play a significant role in the success of your home endeavors. Armed with the right information, you can confidently select Corner Metal Brackets that not only meet but exceed your expectations.

When selecting corner metal brackets for home projects, understanding the different types available is crucial for achieving optimal results. Corner metal brackets primarily come in three types: L-brackets, angle brackets, and corner gussets.

L-brackets, shaped like an "L," are perfect for reinforcing furniture joints, such as shelves, cabinets, and frames. According to industry reports, L-brackets account for nearly 45% of the market share in DIY hardware accessories, indicating their widespread use and reliability.

Angle brackets are versatile and commonly used in both woodworking and metal projects. They offer enhanced stability, allowing for the construction of robust frame structures. Research suggests that angle brackets can increase the longevity of joint connections by up to 50%, making them a preferred choice for homeowners seeking durable solutions. On the other hand, corner gussets, characterized by a triangular shape, are often used in applications that require additional strength and load distribution, such as in the construction of furniture or supportive frameworks.

Each type of corner bracket serves different purposes and can effectively support various load capacities. It’s essential to assess your specific project requirements, including the materials you'll be joining and the expected weight load. By doing so, you can choose the appropriate corner metal bracket that not only meets the functional demands but also contributes to the overall integrity of your home projects.

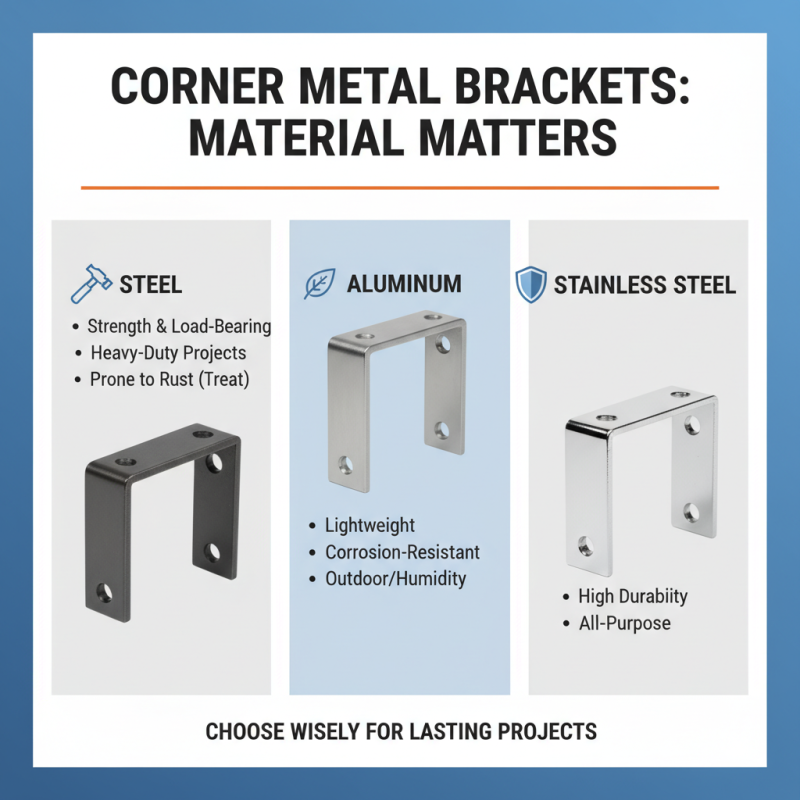

When selecting corner metal brackets for your home projects, several factors come into play to ensure you make the right choice. First and foremost, you should consider the material of the brackets. Common options include stainless steel, aluminum, and carbon steel, each offering different levels of strength and corrosion resistance. For outdoor projects or environments with high moisture, stainless steel is often the best choice due to its durability. In contrast, if you are working on indoor projects with lighter loads, aluminum may suffice and will be easier to manage.

Another critical aspect to consider is the size and load capacity of the brackets. Ensure that the brackets you select can support the weight of the materials they will hold. It's essential to check the specifications and choose brackets that have a load rating matching or exceeding your project needs. Depending on the project’s design, you may also want to evaluate the angle of the brackets; most corner brackets are designed for 90-degree angles, but there are options available for different configurations as well.

Tips: Before purchasing, measure the space where the brackets will be installed carefully. It’s also wise to read customer reviews to gauge the performance of the brackets under real-world conditions. Finally, consider the aesthetic appeal of the brackets, especially for visible applications, as they can contribute to the overall look of your project.

When selecting corner metal brackets for your home projects, the material from which they are made plays a crucial role in their durability and overall performance. Common materials include steel, aluminum, and stainless steel, each offering unique benefits suited for different applications. Steel brackets are known for their strength and load-bearing capacity, making them ideal for heavy-duty projects. However, they can be prone to rust if not coated or treated appropriately. On the other hand, aluminum brackets are lightweight and resistant to corrosion, making them suitable for outdoor use or environments with high humidity.

Stainless steel is another popular option, known for its exceptional resistance to rust and stains. This material is excellent for both aesthetic and functional applications; it offers a sleek appearance while maintaining structural integrity over time. Additionally, when considering the durability of metal brackets, it's essential to assess the gauge, or thickness, of the material. Thicker gauges typically translate to increased strength and durability, which is essential for supporting significant weight. In summary, choosing the right material and understanding its properties will ensure that your corner metal brackets effectively serve their intended purpose while withstanding the test of time.

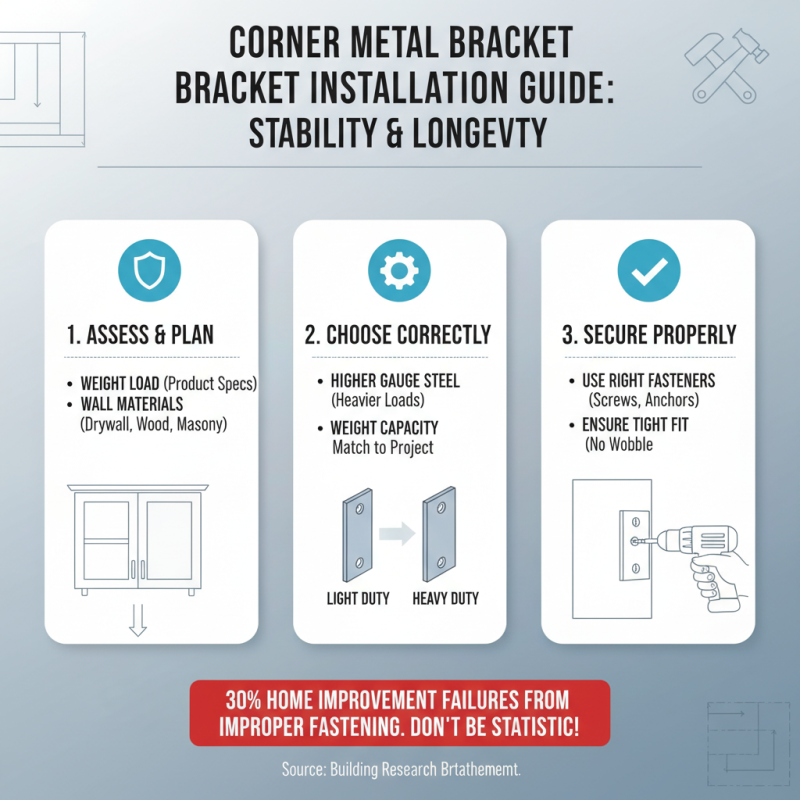

When selecting corner metal brackets for your home projects, it’s crucial to assess weight capacity and load-bearing requirements. These brackets are often used to provide structural support in furniture and shelving, making understanding their weight ratings essential. According to industry standards, the average weight capacity for standard metal brackets ranges from 50 to 500 pounds, depending on their design and material composition. For instance, heavier-duty brackets made from thicker gauge steel are often rated for higher loads, making them suitable for more demanding applications.

Tips for assessing your load-bearing needs include calculating the total weight of the items you plan to place on the shelf or furniture supported by the brackets. Be sure to consider not just the static weight of objects but also dynamic forces such as weight shifting or potential impacts. In general, it’s advisable to choose brackets that can handle at least 1.5 times the expected load to ensure safety and durability. Additionally, reviewing the manufacturer's specifications and any relevant industry ratings can help confirm that you’re selecting the right product for your project.

Always remember that proper installation can significantly affect the performance of corner metal brackets. It’s important to use the correct fasteners and ensure that they are anchored into a solid backing, like wall studs or a stable corner, to maximize load-bearing capacity. Neglecting these factors can lead to structural failure, potentially resulting in damage or injury. By carefully assessing your weight requirements and making informed choices, you can ensure the stability and longevity of your home projects.

When installing corner metal brackets for home projects, proper installation is crucial to ensure stability and longevity. Research from the Building Research Establishment indicates that more than 30% of home improvement failures stem from improper fastening and support elements. To avoid such pitfalls, it’s essential to assess the weight load and wall materials before beginning any project. For instance, heavier cabinetry or shelving requires brackets that are rated to support higher loads, typically identified by their gauge of steel and weight capacity described in product specifications.

The installation process itself demands attention to detail. Start by accurately measuring and marking the locations where the brackets will be affixed. Utilize a level to ensure accuracy; uneven installation can lead to structural failure over time. According to industry standards, lag screws should be used for wood surfaces while masonry screws are recommended for brick or concrete walls. Moreover, experts recommend using a drill with the appropriate bit size to pre-drill holes for enhanced accuracy and to prevent splitting a wood substrate. Following these guidelines can significantly improve the integrity of your projects, ensuring that they withstand the test of time and daily use.