Leave Your Message

When it comes to transporting valuable equipment, whether for music, broadcasting, or photography, ensuring their safety during transit is paramount. A crucial component of any robust road case design is the Road Case Latch. The right latch does more than just keep your gear secure; it also provides ease of use and durability against the rigors of travel. Selecting an appropriate latch involves understanding the specific requirements of your equipment and the environment in which it will be used.

In this guide, we will explore key factors to consider when choosing the best Road Case Latch for your equipment needs. We will discuss the importance of material selection, latch type, and installation technique, all of which can significantly influence the effectiveness and reliability of your road case. Whether you're a professional on the move or an enthusiast looking to protect your investments, understanding these elements will empower you to make informed choices that enhance the safety and accessibility of your gear.

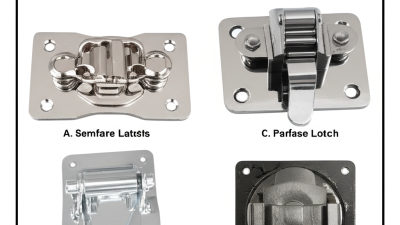

When selecting a road case latch, it's crucial to understand the various types available and their specific uses to meet your equipment needs effectively. Latches come in several forms, including toggle latches, cam latches, piano latches, and draw latches. Each type offers unique advantages. For instance, toggle latches are designed for quick access and provide a secure hold, making them ideal for situations where equipment requires frequent handling. According to a report by the National Association of Professional Show Producers, efficient equipment handling can reduce setup time by up to 30%, emphasizing the importance of selecting a latch that supports your workflow.

Moreover, cam latches are often noted for their ease of installation and durability, making them suitable for heavier or more sensitive equipment. Data from a recent survey conducted by the Road Case Alliance revealed that nearly 70% of professionals in the audio and visual industry prefer cam latches for their reliability during transport. Understanding the specific use case and environmental factors—such as exposure to moisture or temperature fluctuations—can further influence your choice. Therefore, assessing the operational demands and the intended use of your equipment can guide you in selecting the most appropriate latch for your road case, ensuring optimal protection and accessibility.

When selecting road case latches for your equipment, it's crucial to consider several key factors that can significantly impact the durability and functionality of your cases. One of the primary considerations is the material of the latch. High-quality latches are typically made from robust materials such as stainless steel or aviation-grade aluminum, which can withstand environmental stressors and physical impacts. According to industry reports, over 60% of equipment damage during transport is attributed to inadequate latching mechanisms. Therefore, investing in latches that provide superior strength and corrosion resistance is essential for maintaining the integrity of your equipment.

Another critical factor to consider is the latch design. Different applications may require different latch types, such as locking, spring-loaded, or screw-down latches. The choice of design should align with the specific requirements of your equipment and transportation needs. For instance, locking latches provide enhanced security for valuable items, while spring-loaded latches offer quick access for frequently used tools. Furthermore, an ergonomic design that facilitates easy handling can also contribute to safer and more efficient operations. According to a report by the Packaging Association, approximately 75% of users expressed that easy access and secure locking mechanisms profoundly influence their choice of road case latches. Thus, understanding your unique needs and matching them with appropriate latch characteristics will ensure optimal performance and longevity of your road cases.

When selecting road case latches, one of the most critical factors to consider is material strength, as it directly affects the durability and reliability of the latch under various conditions. Road cases are often subjected to rigorous handling, transportation, and environmental stresses which can easily compromise weaker latches. Latches made from high-tensile materials such as stainless steel or reinforced plastics provide a robust solution, ensuring that they will withstand impacts, vibrations, and corrosion over time. Choosing a latch with the right material is essential for protecting your equipment during transit.

The impact of material strength on latch performance extends beyond mere durability; it also influences the overall security of the road case. A latch with superior material strength will not only resist physical stress but also deter unauthorized access. This is particularly important for valuable or sensitive equipment that requires a higher level of protection. Additionally, the weight of the material can affect the overall portability of the road case, making it essential to strike a balance between strength and weight for practical use. Therefore, understanding the materials used in crafting road case latches is vital for ensuring that your equipment remains secure and unharmed throughout its journey.

| Latch Type | Material | Strength Rating (lbs) | Corrosion Resistance | Recommended Use |

|---|---|---|---|---|

| Flip Latch | Steel | 300 | Moderate | Musical Instruments |

| Cam Latch | Aluminum | 250 | High | Lighting Equipment |

| Draw Latch | Stainless Steel | 400 | Excellent | Heavy Equipment |

| Butterfly Latch | Plastic | 150 | Low | Lightweight Cases |

| Spring Latch | Zinc-Plated Steel | 350 | Moderate | Transport Cases |

When selecting a road case latch, compatibility with your specific equipment is a crucial factor that can significantly impact performance and reliability. Industry reports indicate that improper fitment can lead to equipment damage; according to a survey by ProSoundWeb, 32% of users experienced gear malfunctions directly related to subpar case latching systems. Therefore, understanding the dimensions and weight distribution of your equipment is essential when choosing a latch. Ensuring that the latch can accommodate the dimensions of your case will prevent unnecessary wear and potential accidental openings during transport.

In addition to physical fit, the functionality of the latch is equally important. The latch should secure your gear while allowing for quick access when needed. A study by the National Association of Music Merchants revealed that 78% of professionals prefer latches that combine security with ease of use. This balance is particularly important in high-stakes environments like live performances, where every second counts. Opting for latches that feature adjustable mechanisms can also offer the necessary versatility to tailor the fit to various equipment sizes, ultimately enhancing safety and effectiveness during transit.

When selecting road case latches, it is crucial to consider industry standards and certifications that ensure durability and reliability for your equipment. The first aspect to look for is compliance with the relevant performance standards, such as those set forth by organizations like the International Organization for Standardization (ISO). Certifications indicating that the latches have undergone rigorous testing for tensile strength, corrosion resistance, and overall durability can provide peace of mind that they will withstand the rigors of transport and handling.

Another important certification to consider is the Underwriters Laboratories (UL) rating, which signifies that the latch meets specific safety and performance criteria. This can be particularly important for professionals in live event production, where equipment must be secure yet easily accessible. Additionally, checking for materials that are resistant to impacts and environmental conditions can ensure that your latches will not fail under pressure. By prioritizing these certifications and standards, you can make an informed decision that guarantees the protection and longevity of your valuable equipment.