Leave Your Message

In the realm of manufacturing and assembly, the choice of tools plays a pivotal role in achieving efficiency and precision. Among these tools, the 90 Degree Toggle Clamp stands out as an essential component for securing workpieces during operations. According to a report by MarketsandMarkets, the global toggle clamp market is projected to grow significantly, with an estimated CAGR of 5.8% from 2020 to 2025, highlighting the increasing reliance on these key components in various industrial applications. When selecting the right 90 Degree Toggle Clamp for your project needs, it's critical to consider factors such as load capacity, clamping force, and material compatibility. Understanding these specifications, along with the operational requirements of specific applications, can ensure optimal performance and enhance productivity in manufacturing processes.

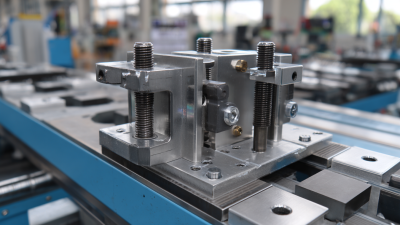

90-degree toggle clamps are essential tools in various industries, offering a reliable method for securing workpieces during machining, assembly, or fabrication processes. Understanding the fundamentals of these clamps can greatly enhance project efficiency and safety. According to a recent report from the Industrial Fasteners Institute, about 25% of manufacturing downtime is attributed to inefficient workholding solutions. Utilizing toggle clamps can significantly reduce this downtime by providing a secure hold, allowing for quicker transitions between tasks.

In applications ranging from woodworking to metalworking, the effectiveness of a 90-degree toggle clamp lies in its design, which enables quick adjustments and strong clamping force. These clamps typically feature a lever arm that provides mechanical advantage, ensuring that even minimal operator effort can achieve a secure grip. According to a technical study published by the International Journal of Advanced Manufacturing Technology, using a proper clamping mechanism can increase productivity by up to 30%. Selecting a toggle clamp suited to the specific weight and shape of your workpieces ensures consistent and reliable performance, making this tool a valuable asset in any production environment.

When selecting the right 90-degree toggle clamp for your project needs, it's essential to focus on several key features that can significantly impact the clamp's performance and suitability for your application. First, consider the material construction of the clamp. Durable materials such as steel or stainless steel offer robustness and longevity, which is crucial for projects involving heavy loads or frequent use.

Another important feature to evaluate is the clamp's holding capacity. Depending on the specific requirements of your project, ensure that the clamping force meets your load requirements without compromising safety. Additionally, check the clamp's design for ease of use and adjustability, as these factors can enhance efficiency when securing workpieces.

Tips: Always look for toggle clamps with quick-release mechanisms for improved workflow. If your project involves diverse applications, consider clamps that come with interchangeable tips to adapt to various shapes and sizes. Finally, reviewing user feedback on performance can also provide valuable insights into how well a toggle clamp will meet your specific project needs.

When selecting the right 90-degree toggle clamp for your project, it's crucial to compare different types available on the market. The versatility of toggle clamps allows them to cater to various applications, from woodworking to automotive assembly. For instance, a report by Market Research Future highlights that the toggle clamp industry is expected to see significant growth, with a projected CAGR of 5.2% from 2021 to 2027. This increase indicates a rising demand for reliable and flexible fastening solutions across multiple sectors.

Different types of 90-degree toggle clamps, such as horizontal, vertical, and automatic variants, offer unique benefits tailored to specific project needs. Horizontal toggle clamps excel in providing strong holding force while minimizing vertical space requirements, making them ideal for compact setups. Conversely, vertical toggle clamps are suitable for larger workpieces where access is not restricted. Furthermore, automatic toggle clamps can enhance productivity by reducing the time taken to engage and disengage the clamps, a vital feature in high-volume manufacturing situations. Understanding these distinctions will help you make an informed decision that aligns with your project's requirements.

Different types of 90-degree toggle clamps, such as horizontal, vertical, and automatic variants, offer unique benefits tailored to specific project needs. Horizontal toggle clamps excel in providing strong holding force while minimizing vertical space requirements, making them ideal for compact setups. Conversely, vertical toggle clamps are suitable for larger workpieces where access is not restricted. Furthermore, automatic toggle clamps can enhance productivity by reducing the time taken to engage and disengage the clamps, a vital feature in high-volume manufacturing situations. Understanding these distinctions will help you make an informed decision that aligns with your project's requirements.

When selecting a 90 degree toggle clamp for your project, evaluating the weight capacity is crucial. Each clamp comes with a specified maximum weight it can handle, which is critical for ensuring safety and efficiency during use. Overloading a clamp can lead to failure, potentially causing damage to both the project and the user. Therefore, it’s essential to assess the weight requirements of your materials and choose a clamp that comfortably exceeds those figures. Understanding the specific weight distribution and peak loads during the project will aid in making an informed decision.

In addition to weight capacity, the durability of the materials used in the toggle clamp plays a significant role in its longevity and performance. Toggle clamps are typically constructed from various metals and plastics, each with different strengths and resistance to wear and corrosion. For projects exposed to harsh environments or heavy usage, opting for clamps made from high-grade materials, such as stainless steel, can enhance durability and resilience. Evaluating both the weight capacity and material durability ensures that the selected toggle clamp meets the demands of your project, allowing for reliable and effective operation over time.

When using 90 degree toggle clamps, proper installation and maintenance are crucial for ensuring functionality and longevity. First and foremost, it is essential to mount the clamps securely onto a stable surface. Ensure the pivot points have enough clearance to avoid any obstruction during operation, which can impede clamp performance. Moreover, always check that the toggle mechanism engages smoothly; any resistance may indicate a need for adjustment or lubrication.

Maintenance should involve regular visual inspections for any signs of wear or damage. Using a light oil or lubricant on the pivot points can help maintain smooth operation. It’s important to tighten any loose screws or bolts promptly, as fluctuations can lead to misalignment and decreased efficiency over time. Additionally, keep the clamps clean from dust and debris to prevent corrosion and ensure optimal performance. By following these tips, you can significantly enhance the reliability and service life of your 90 degree toggle clamps.

| Clamp Type | Load Capacity | Material | Jaw Opening | Weight | Best Applications |

|---|---|---|---|---|---|

| Standard Toggle Clamp | 500 lbs | Steel | 2.5 inches | 1.5 lbs | Woodworking, Metal Fabrication |

| Heavy-Duty Toggle Clamp | 1000 lbs | Stainless Steel | 3 inches | 3 lbs | Industrial Applications |

| Mini Toggle Clamp | 200 lbs | Aluminum | 1.5 inches | 0.5 lbs | Hobby Projects, Small Fixtures |

| Vertical Toggle Clamp | 400 lbs | Cast Iron | 2 inches | 2 lbs | Assembly Fixtures, Production Lines |