Leave Your Message

When it comes to protecting valuable equipment during transport, the choice of a Flight Case Hinge is often an overlooked but critical decision. According to a recent industry report from the International Association of Packaging Professionals, incorrect hinge selection can lead to a 30% increase in damage rates during shipping, emphasizing the importance of choosing the right fitness for your needs. With a variety of materials, sizes, and functionalities available, understanding the specifications and performance of different flight case hinges is crucial.

This checklist aims to guide you in evaluating the essential factors, ensuring that your selected hinges not only enhance durability but also align with weight and cost considerations, thus safeguarding your equipment while optimizing logistics.

When selecting the right flight case hinge, durability and longevity are paramount considerations. The material composition of the hinge significantly affects its performance under various conditions. Innovations in production technologies, akin to trends in sustainable building materials, have led to the development of hinges that are not only robust but also lightweight. For instance, hinges made from advanced composite materials are proving to be more resilient, resisting wear and tear that often plagues traditional metal counterparts.

Moreover, the design of the hinge plays a critical role in its functionality and lifespan. Hinges that incorporate modern engineering principles can withstand repeated use and environmental challenges, ensuring that your flight case remains secure and functional over time. Choosing a hinge with enhanced resistance to corrosion and fatigue can further extend its usability, making it an essential factor when considering your flight case's overall durability. By taking these key factors into account, users can make informed decisions that align with their specific needs and usage scenarios.

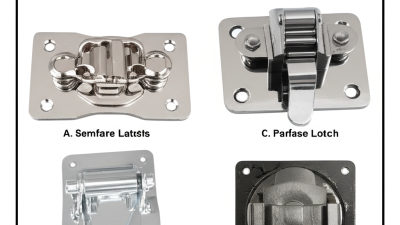

When selecting the appropriate hinge for a flight case, understanding the different types available is essential. One of the most common types is the piano hinge, which offers continuous support along its length, making it ideal for heavier cases that require added durability. The pros include ease of installation and strong construction, while the cons may involve requiring more space and being less adaptable for design variations.

Another popular option is the T-hinge, which allows for a more flexible design and can be used in various configurations. These hinges are particularly beneficial for cases that require a quick access opening without sacrificing structural integrity. However, they may not provide the same level of strength as a piano hinge under heavy loads. Additionally, lid hinges, designed specifically for lids, can enhance the functionality of a case, providing a smooth opening and closing mechanism. Nonetheless, their load-bearing capacity might be limited compared to other types. Understanding these hinges' strengths and weaknesses will allow you to select the best option tailored to your specific flight case needs.

When selecting the right hinge for your flight case, material choice plays a crucial role in ensuring durability and functionality. Traditionally, flight case hinges are made from materials such as steel, aluminum, and plastic. According to a report by the International Organization for Standardization (ISO), metal hinges, particularly those made from stainless steel, exhibit exceptional strength and corrosion resistance, which is vital for frequent travel and varying climatic conditions. Steel hinges can withstand high impact, making them ideal for heavy equipment cases, while aluminum offers a lightweight alternative without sacrificing structural integrity.

On the other hand, plastic hinges have gained popularity due to their ease of use and resistance to rust. The Global Plastic Hinge Market Report indicates that the demand for high-quality, durable plastic hinges has increased by 15% in the past year among manufacturers of audio-visual equipment cases. Their lightweight nature reduces overall shipping costs, while innovative designs include features like built-in stops or easy-release mechanisms. When choosing the right material for your flight case hinge, consider factors such as weight limits, environmental exposure, and the specific use cases for your equipment to make a well-informed decision.

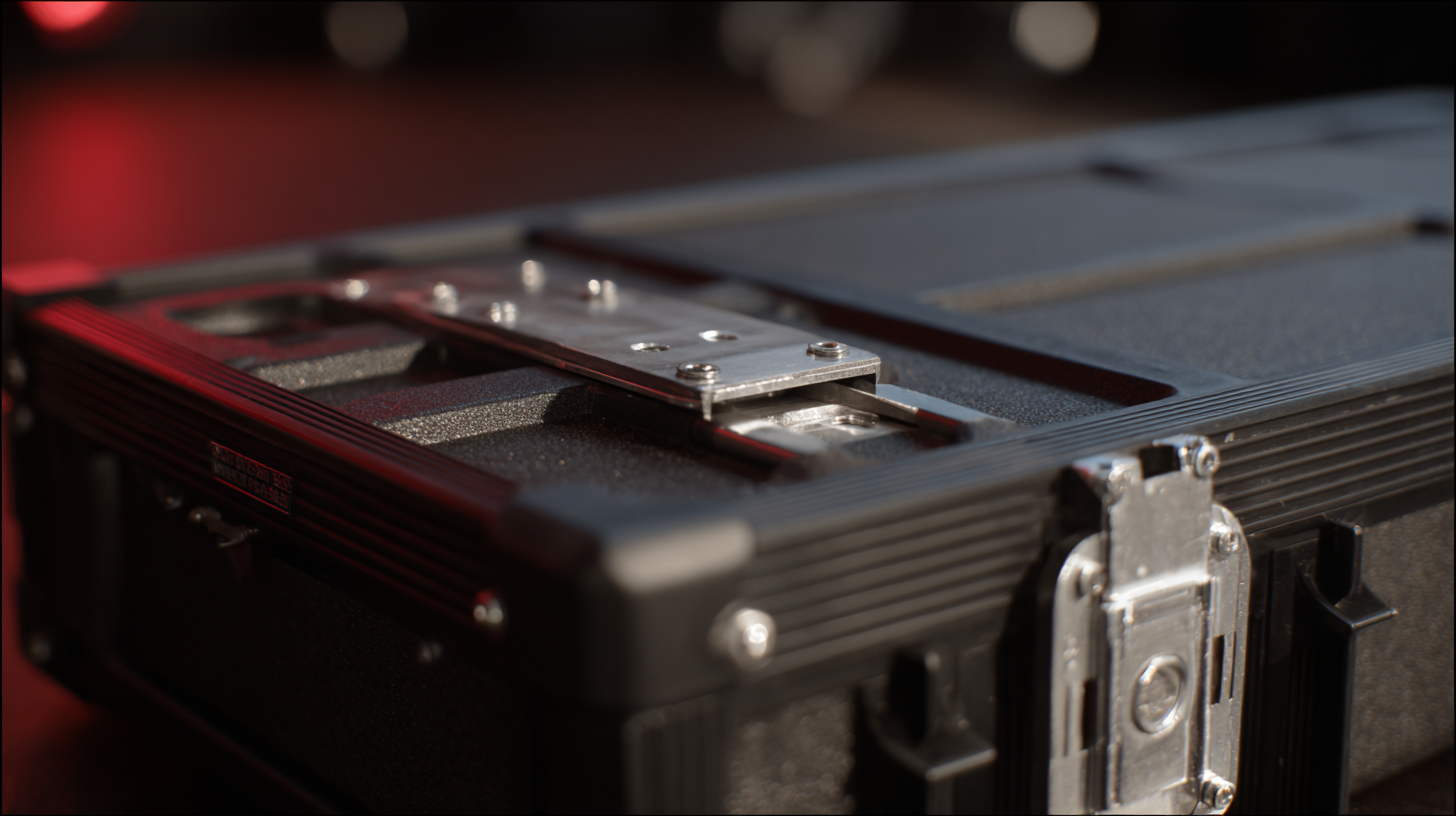

When selecting the appropriate flight case hinge, understanding weight capacity and load distribution is crucial for ensuring safety and functionality. Flight cases often carry valuable equipment, whether they are used for musical instruments, sensitive electronics, or camera gear. The chosen hinge must be strong enough to support the total weight of the case and its contents without risking failure during transport. Consider the materials used in the hinge; metals like stainless steel or aluminum typically offer superior strength compared to plastic alternatives. Assessing the weight each hinge can bear is essential in preventing accidents that may lead to damaged items or compromised safety.

Beyond weight capacity, the distribution of that load affects the performance of the hinge. When a flight case is in use, the weight is not always evenly distributed; hence, the design of the hinge should accommodate this variability. For instance, choosing a wide hinge with multiple attachment points can help distribute weight more evenly across the case, reducing stress on individual components. Additionally, consider the mounting position—top-mounted hinges can offer a different load handling capability compared to side-mounted options. By paying attention to these details, you can select hinges that not only support the weight but also enhance the overall durability and longevity of your flight case.

When it comes to ensuring the longevity of your flight case hinges, regular maintenance is crucial. Start by routinely inspecting the hinges for any signs of wear, rust, or damage. A simple visual check can help identify potential issues early on. If you notice any dirt or debris, clean the hinges with a soft cloth and a mild cleaning solution. Avoid using harsh chemicals that can corrode the metal. Lubricating the hinges with a silicone spray or a similar lubricant can also prevent stiffness and ensure smooth operation, which is essential for protecting the contents of your flight case.

Additionally, consider the environment in which your flight case is stored and used. Extreme temperatures and humidity can adversely affect the materials of the hinges. When possible, keep your flight case in a climate-controlled setting to minimize these effects. If your cases are frequently used for travel, be mindful of the handling they receive; rough treatments can stress hinges over time. By staying proactive with these maintenance tips, you can extend the life of your flight case hinges, ensuring they continue to perform well in protecting your valuable equipment.