Leave Your Message

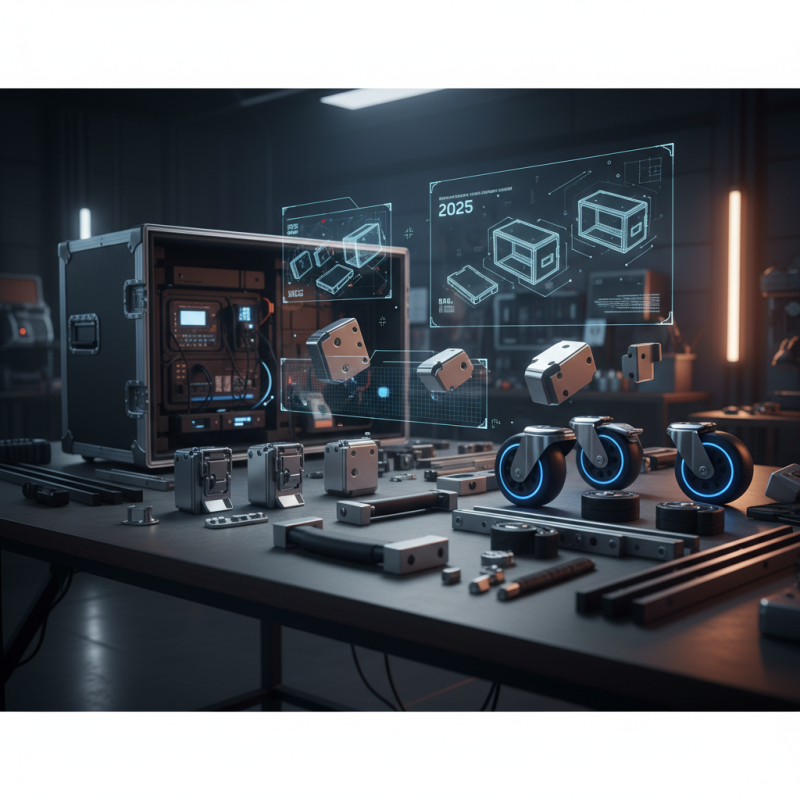

As we step into 2025, the importance of choosing the right Road Case Hardware has never been more critical for professionals in the music, broadcasting, and event production industries. With advancements in technology and evolving industry standards, road cases have transformed from mere protective enclosures to sophisticated solutions that cater to the nuances of modern equipment. Selecting the appropriate hardware not only ensures the safety and longevity of your gear but also enhances functionality and ease of transport.

In this guide, we will explore the various factors to consider when choosing Road Case Hardware for your specific needs. From material durability and weight management to the ease of installation and mobility, understanding these elements will enable you to make informed decisions that align with your operational requirements. Whether you are a seasoned professional or an emerging talent, this overview will provide valuable insights to help you secure your equipment effectively while optimizing performance on the go.

When selecting road case hardware for your equipment, there are several crucial factors to consider to ensure protection and durability. One of the most important considerations is the material of the hardware. Opt for high-quality metals or reinforced plastics that can withstand the rigors of transportation. Evaluating the weight of the hardware is also essential, as heavier components can add unnecessary bulk to your road case, impacting portability. Look for a balance between lightweight materials that offer sufficient protection.

Another factor to consider is the type of closure system used in the hardware. Latches and locks should be robust yet easy to operate. Heavy-duty snap locks or TSA-approved locks can provide added security while ensuring quick access when needed. Additionally, consider the compatibility of the hardware with various types of road cases. Hardware that offers versatility can be repurposed if you decide to upgrade or change your cases down the line.

**Tips:** Always factor in the environment in which the road case will be used. For outdoor events, consider hardware with weatherproof features to protect against moisture and dust. Regularly check and maintain the hardware to ensure optimal performance; cleaning and lubricating moving parts can prolong their lifespan. Finally, invest time in reading reviews or seeking recommendations from fellow professionals to discover reliable hardware options.

When selecting road case hardware in 2025, it's essential to understand the different types available to ensure optimal protection and functionality for your equipment. Common hardware options include latches, handles, and wheels, each designed to enhance durability and ease of transport.

Latches come in various styles, such as butterfly or drawbolt, catering to different security needs. Handles can vary from recessed to swivel types, allowing for comfortable carrying or secure mounting. Wheels are crucial for mobility; options like swivel and fixed wheels can help navigate tight spaces while providing stability.

Tip: Always consider the weight of your equipment when choosing wheels. Heavier items may require larger, sturdier wheels to ensure easy transport without compromising safety.

In addition to the fundamental components, consider accessories like corner protectors, foam inserts, and dividers.

Corner protectors are vital in safeguarding against impact during transit, while foam inserts provide custom-fit cushioning for delicate instruments. Dividers can help organize multiple items within a single case, preventing movement and potential damage.

Tip: Evaluate the specific requirements of your equipment when selecting dividers to maximize interior space while ensuring that every item is securely held in place.

When selecting road case hardware, the material choices can significantly affect both durability and weight. In 2025, as the industry continues to evolve, materials such as polypropylene, aluminum, and high-density polyethylene (HDPE) are gaining traction due to their unique properties. According to recent industry reports, polypropylene offers superior resistance to various chemicals and environmental factors, making it an excellent option for outdoor use. Additionally, aluminum is favored for its lightweight strength and ability to withstand impact, making it a common choice among professionals transporting sensitive equipment.

Tip: When assessing materials, consider the specific environments in which your equipment will be used. For example, if your gear will frequently be exposed to moisture or extreme temperatures, selecting road cases made of HDPE could provide the necessary durability and protection against these elements.

Furthermore, the trend towards lightweight solutions is driving the innovation of composite materials that combine the benefits of strength and reduced weight. According to industry analysts, these composites can reduce weight by up to 30% compared to traditional materials without compromising structural integrity. Choosing the right material not only ensures the safety of your equipment but also enhances portability and ease of use.

Tip: Always weigh the importance of durability against the need for mobility. For frequent travelers, investing in lighter materials can lead to less fatigue and improved efficiency during setup and transport.

| Material | Weight (lbs) | Durability Rating | Cost per Unit ($) | Best Use Case |

|---|---|---|---|---|

| Plywood | 25 | 8/10 | 150 | General Equipment |

| Plastic | 15 | 6/10 | 100 | Lightweight Equipment |

| Aluminum | 20 | 9/10 | 200 | Mobile Sound Equipment |

| Fiberglass | 18 | 7/10 | 250 | Fragile Equipment |

| Carbon Fiber | 12 | 10/10 | 500 | High-End Equipment |

When selecting road case hardware for various types of equipment in 2025, compatibility becomes paramount. According to industry reports, the professional audio and video equipment market is projected to reach $44.4 billion by the end of this year, highlighting the increasing diversity in equipment types and the subsequent need for adaptable hardware solutions. Whether dealing with audio mixers, lighting rigs, or camera equipment, ensuring that the hardware precisely fits the dimensions and weight specifications of the equipment is essential for maintaining functionality and protecting investments.

Moreover, the importance of material compatibility cannot be overlooked. A recent study by the Association of Professional Equipment Manufacturers indicates that hardware crafted from durable materials such as aluminum and reinforced plastic significantly extends the life of both the case and the equipment it houses. In 2023, over 60% of equipment damage reports linked to inadequate road case fittings stemmed from poor hardware choices, emphasizing that investing in components engineered for specific applications not only safeguards assets but also simplifies transport logistics. Thus, selecting road case hardware that aligns with the specific needs and parameters of different equipment types is critical for professionals navigating the rapidly evolving landscape of 2025's equipment requirements.

In 2025, the landscape of road case hardware design is evolving to prioritize enhanced protection for valuable equipment. As the demand for reliable transport solutions increases, manufacturers are focusing on innovative materials and designs that offer greater durability and impact resistance. This trend is driven by advancements in technology, enabling the creation of lighter yet stronger components. For instance, aerospace-grade materials are becoming more common, ensuring that road cases can withstand harsh conditions while minimizing weight.

Moreover, the integration of smart technology is on the rise, allowing for better monitoring of equipment during transit. Features such as temperature and humidity sensors can provide real-time data, alerting users to potential risks before they become significant issues. Additionally, customizable designs are gaining popularity, allowing users to tailor hardware configurations for their specific gear, ultimately enhancing protection and usability.

As the industry moves forward, these trends in road case hardware design will not only improve the safety of equipment but also transform how professionals approach equipment transportation and storage.