Leave Your Message

In the fast-paced world of manufacturing, efficiency is paramount, and tools that enhance operational performance are invaluable. One such tool is the Adjustable Toggle Clamp, which has become crucial in various industries for improving productivity and precision. According to a report by the Manufacturing Institute, approximately 80% of manufacturers are continuously seeking innovative solutions to streamline their processes and minimize downtime. Adjustable Toggle Clamps offer a flexible solution that can adapt to a wide range of applications, from assembly lines to machining tasks. By providing superior gripping force and ease of use, these clamps not only enhance workflow efficiency but also significantly reduce the time required for setup and changeovers. As the demand for higher production rates grows, integrating Adjustable Toggle Clamps into manufacturing workflows emerges as a strategic move for companies aiming to gain a competitive edge.

In today's competitive manufacturing landscape, enhancing efficiency is paramount. One innovative approach to boost productivity is the use of adjustable toggle clamps. These tools not only streamline assembly processes but also contribute to significant time savings. The global automotive plastic fasteners market, projected to reach USD 4.66 billion by 2024 with a CAGR of 6.0% through 2030, highlights the growing importance of efficient fastening solutions in manufacturing environments.

Adjustable toggle clamps allow for quick and secure holding of parts, ensuring precision and reducing the likelihood of errors during assembly. This adaptability can optimize workflow, particularly in high-speed production lines where time is of the essence. Implementing these clamps can result in not only improved operational efficiency but also enhanced product quality, satisfying market demands better.

Tips for maximizing the benefits of adjustable toggle clamps include:

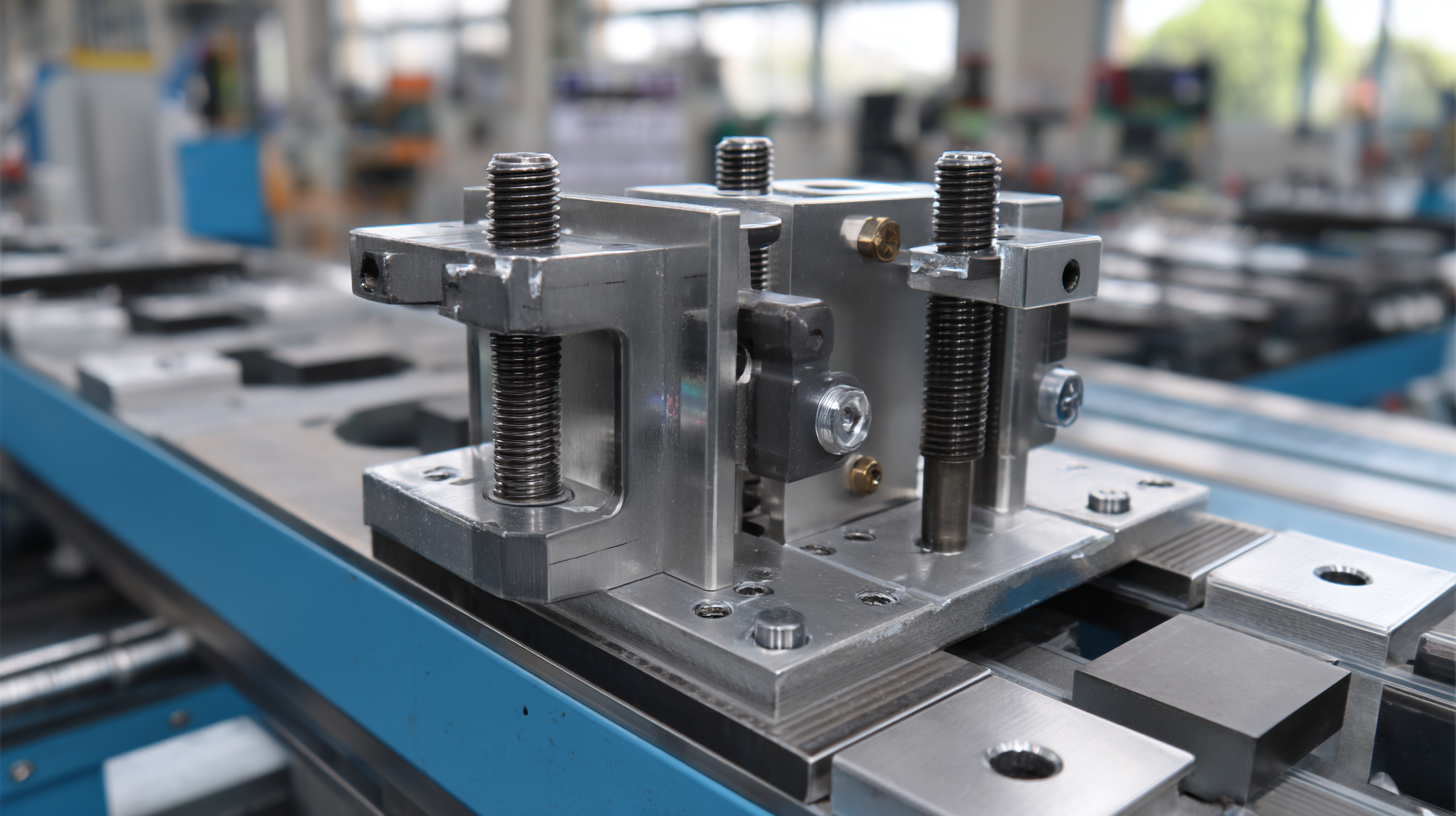

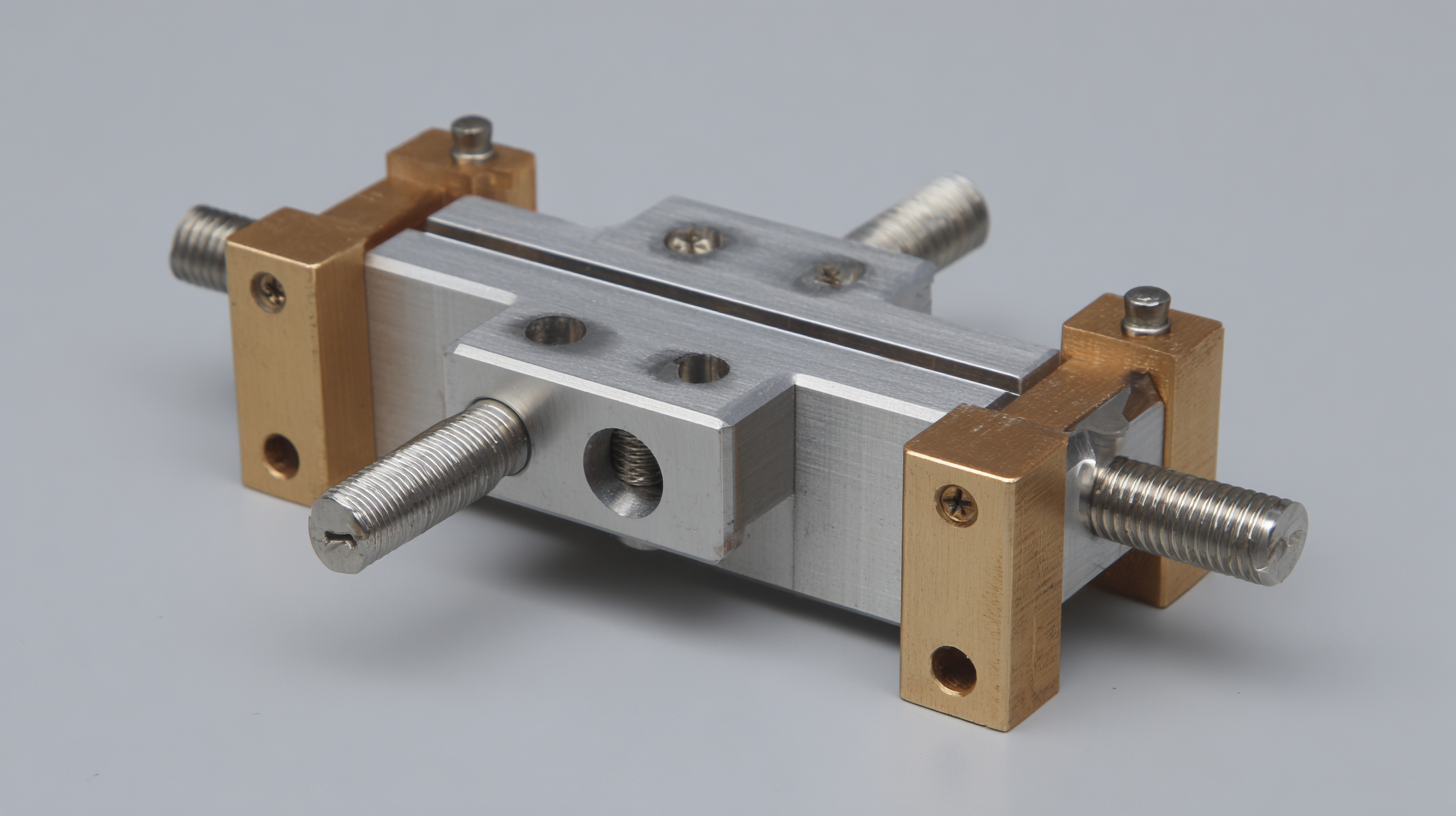

In the realm of manufacturing, the efficiency of production processes can be significantly influenced by the tools used, particularly adjustable toggle clamps. These clamps are essential for securely holding workpieces in place, allowing for precision and safety during operations. A comparative analysis of adjustable toggle clamp designs reveals that factors such as adjustment mechanism, material quality, and ergonomics play crucial roles in determining optimal performance.

One key differentiator among various clamp designs is the adjustment mechanism. High-quality clamps feature a quick-release lever or a threaded adjustment screw, enabling operators to swiftly change the clamping force and height based on the specific requirements of their tasks. This flexibility not only enhances productivity but also minimizes downtime, as operators can seamlessly transition between different workpieces. Moreover, clamps constructed from durable materials, such as stainless steel or reinforced plastics, ensure longevity and resistance to wear, contributing to consistent performance over time.

Ergonomics also cannot be overlooked in the design of adjustable toggle clamps. A well-designed clamp should offer comfortable grip options and reduce strain on the operator's hand during use. Designs that incorporate enhancements, such as rubberized grips or adjustable handle lengths, can lead to more efficient operations and increased worker satisfaction. Thus, by carefully analyzing and selecting adjustable toggle clamp designs that prioritize these elements, manufacturers can significantly enhance their operational efficiency and maintain high-quality standards in their production processes.

| Clamp Design | Max Holding Force (lbs) | Adjustability Range (inches) | Material | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Design A | 750 | 1.5 - 3.5 | Steel | 2.0 | 35 |

| Design B | 600 | 2.0 - 4.0 | Aluminum | 1.5 | 40 |

| Design C | 800 | 1.0 - 3.0 | Carbon Steel | 2.2 | 50 |

| Design D | 700 | 1.5 - 3.5 | Stainless Steel | 2.5 | 45 |

In the manufacturing sector, selecting the right adjustable toggle clamp is paramount for optimizing workflow and enhancing efficiency. Recent industry reports indicate that proper clamping techniques can improve production cycle times by up to 25%. This efficiency gain is particularly evident in assembly lines, where the speed and ease of use of toggle clamps directly influence overall productivity. By implementing adjustable toggle clamps with ergonomic designs, manufacturers can not only reduce operator fatigue but also minimize time wasted on setup adjustments.

Choosing the right clamp involves understanding specific operational needs. For example, a study by the Manufacturing Institute revealed that companies utilizing adjustable toggle clamps tailored to their product line significantly cut down on errors associated with misalignment—by as much as 30%. Investing in high-quality clamps that offer quick-release features also enhances workflow continuity, ensuring that machine downtimes are dramatically reduced. Moreover, adopting clamps with adjustable tension settings allows for versatility across various projects, making them an invaluable asset in dynamically changing manufacturing environments.

When selecting adjustable toggle clamps for manufacturing, there are several key features to consider that can significantly enhance efficiency in your processes. First, it’s essential to look for clamps with high clamping force capabilities. This ensures that your workpieces remain securely in place during operations, minimizing the risk of movement or misalignment. Additionally, consider the material and build quality of the clamps; robust designs made from durable materials can withstand the demands of heavy use in manufacturing environments.

Tips: Always check the adjustable range of the toggle clamps. A broader adjustment range allows for versatility in handling various workpiece sizes, improving workflow efficiency. Furthermore, examine the ease of operation; clamps that require minimal effort to engage and disengage can save valuable time during production runs.

Moreover, you should think about the mounting options available with the clamps. Having a variety of mounting choices can simplify the installation process and allow for quick changes in setup. This adaptability can greatly enhance your production line's overall efficiency, enabling swift transitions between different tasks.

Adjustable toggle clamps have emerged as vital components in manufacturing processes, significantly enhancing efficiency across various industries. A recent report by the International Federation of Robotics indicated that manufacturers leveraging automated systems combined with traditional mechanical tools like toggle clamps can increase production efficiency by up to 30%. This improvement is particularly evident in assembly lines, where adjustable toggle clamps ensure consistent pressure, quick adjustments, and easy operation, reducing the cycle time immensely.

In industries such as automotive and aerospace, where precision is paramount, adjustable toggle clamps are utilized to maintain exact tolerances during production. According to a study by the Society of Manufacturing Engineers, implementing these clamps in CNC machining and welding applications can lead to a reduction in rework by over 20%. This not only streamlines operations but also enhances product quality, ensuring that manufacturers meet stringent industry standards while minimizing waste and operational costs. As adjustable toggle clamps continue to evolve, their role in optimizing manufacturing efficiency will undoubtedly expand, providing businesses with the tools needed to thrive in a competitive marketplace.