Leave Your Message

In the rapidly evolving landscape of manufacturing, quality has emerged as a cornerstone of competitive advantage, particularly in the production of specialized components like spring loaded handles. According to a report by MarketsandMarkets, the global market for industrial handles, which includes spring loaded variants, is projected to reach USD 1.2 billion by 2025, growing steadily at a CAGR of 5.4%. This growth underscores the pivotal role that spring loaded handles play in various applications, ranging from automotive to consumer products.

As manufacturers strive to enhance their offerings, the emphasis on quality-centric approaches has never been greater, particularly in China, which is recognized as a leading producer of high-quality spring loaded handles. However, this sector faces significant challenges, including supply chain complexities and the need for adherence to international quality standards. Addressing these issues is essential for companies aiming to excel in global markets, ultimately fostering innovation and ensuring lasting customer satisfaction.

Quality-centric manufacturing has become a hallmark of China's spring loaded handle industry, positioning the country as a key player in global markets. This approach emphasizes the importance of producing high-quality products while optimizing efficiency and cost-effectiveness. Chinese manufacturers have integrated advanced technologies and stringent quality control measures into their processes, ensuring that every spring loaded handle meets international standards. As a result, they have gained the trust of clients worldwide who seek reliable and durable solutions for various applications.

In this competitive landscape, understanding the nuances of quality-centric manufacturing is essential for businesses looking to source components from China. This model not only focuses on the final product but also on the entire production process, from material selection to assembly and testing. By prioritizing quality at every step, manufacturers can reduce waste, enhance product longevity, and ultimately deliver superior value to customers. As global demand for high-performance spring loaded handles continues to rise, manufacturers in China are well-equipped to meet these challenges through their unwavering commitment to quality.

This chart illustrates the percentage of manufacturers in China's spring loaded handle industry that emphasize different quality standards. The data shows the industry's focus on various aspects of quality-centric manufacturing, reflecting the growing importance of product quality in global markets.

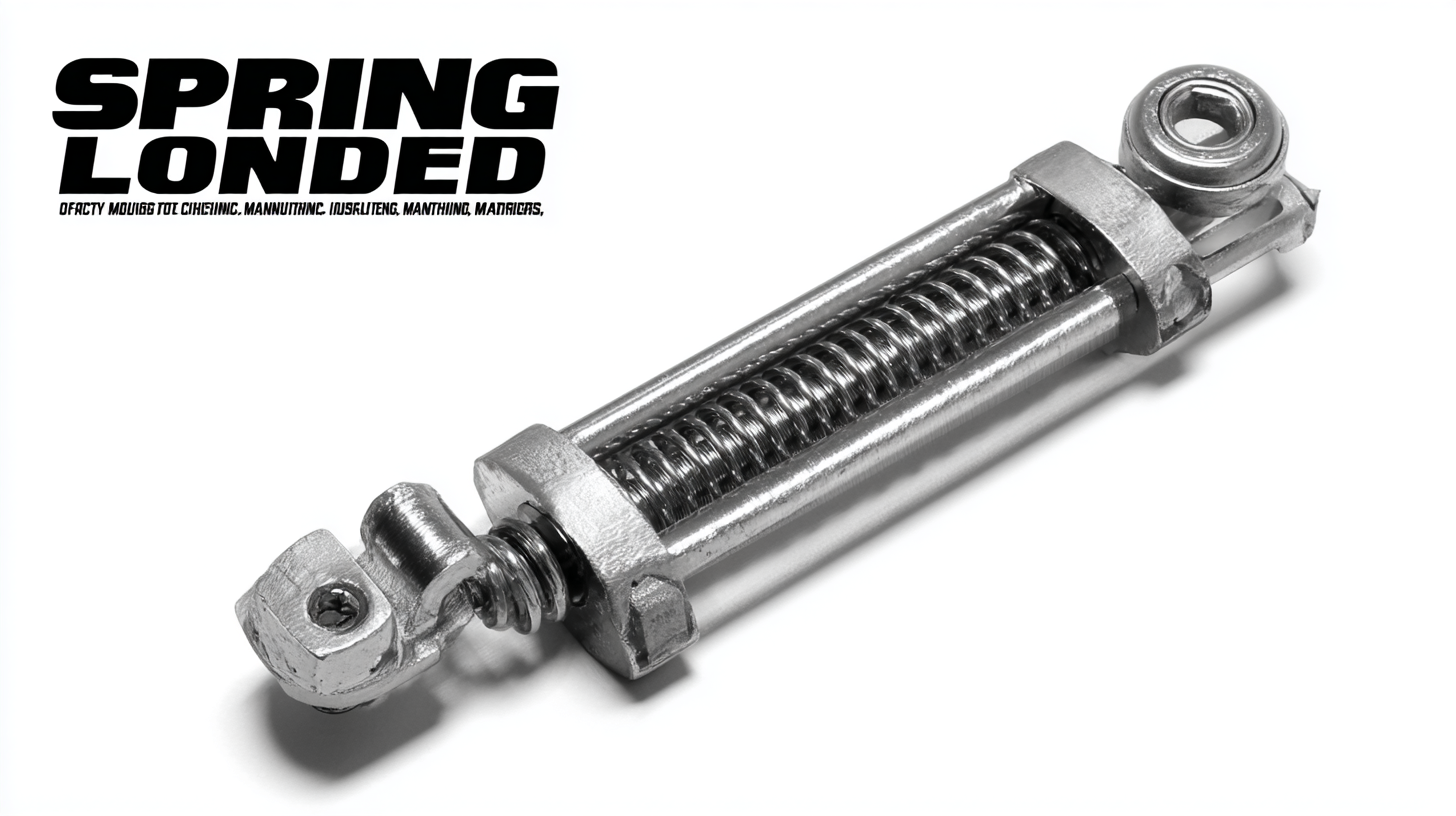

In the realm of quality-centric manufacturing, China's spring loaded handles have garnered attention as a top choice for global markets. These handles are designed with a diverse range of features that enhance functionality and user experience. One key attribute is their robust construction, utilizing high-quality materials that ensure durability even under heavy usage. This resilience makes them ideal for various applications, from automotive to industrial settings, where performance is paramount.

Another standout feature of these spring loaded handles is their ergonomic design, which prioritizes user comfort. The handles are crafted to provide a secure and comfortable grip, reducing fatigue during prolonged use. Additionally, the innovative spring mechanism allows for smooth operation, offering a seamless experience for users. With customizable options available, manufacturers can tailor these handles to meet the specific requirements of their target markets, ultimately enhancing their appeal on a global scale. As countries continue to seek reliable and efficient hardware solutions, China's spring loaded handles are positioned to meet these demands effectively.

In the realm of quality-centric manufacturing, ensuring superior standards at every stage of the process is crucial, especially for China’s spring loaded handles designed for global markets. The manufacturing journey begins with meticulous material selection, where high-quality raw materials are chosen to withstand wear and tear. This foundational step not only impacts the durability of the handle but also influences its safety and performance.

Tips: Always source materials from reputable suppliers and conduct thorough inspections upon arrival. This practice helps in maintaining quality and reducing defects in the finished product.

As production commences, implementing rigorous quality checks at each phase becomes essential. From initial assembly to final finishing, manufacturers should deploy systematic evaluations to identify potential issues early on. This proactive approach enables timely adjustments and ensures that each handle meets or exceeds international quality standards.

Tips: Utilize checklists and automated testing tools to streamline quality assessments throughout the manufacturing stages. This can significantly enhance efficiency and reliability in the production process.

| Stage of Manufacturing | Quality Assurance Check | Testing Method | Frequency | Responsible Department |

|---|---|---|---|---|

| Raw Material Acquisition | Material Certification | Chemical Composition Analysis | Every Batch | Procurement |

| Manufacturing Process | Dimensional Accuracy | CMM Inspection | Hourly | Production |

| Final Assembly | Functional Testing | Load Testing | Every Unit | Quality Control |

| Packaging | Packaging Integrity | Visual Inspection | Per Shipment | Logistics |

| Customer Feedback | Post-Sales Quality Audit | Surveys & Reviews | Continuous | Customer Service |

In the realm of manufacturing, quality control is paramount, especially in competitive markets like spring loaded handles.

China's commitment to excellence begins with stringent quality control standards that are woven into every stage of production.

Manufacturers implement rigorous testing protocols to ensure that each spring loaded handle not only meets but exceeds international safety and performance benchmarks.

This meticulous attention to detail helps safeguard the reputation of Chinese manufacturers while catering to the demands of global markets.

To achieve these high standards, manufacturers employ advanced technologies and methodologies, such as Six Sigma and Total Quality Management (TQM).

These frameworks enable continuous improvement and foster a culture of quality among workers. Regular audits and compliance checks ensure that every batch of products adheres to the established guidelines, making the process transparent and reliable.

As a result, consumers worldwide can trust the durability and functionality of spring loaded handles produced in China, reflecting a commitment to quality that resonates in every market segment.

In today's competitive landscape, expanding the global reach of quality-centric manufacturing, particularly in the spring loaded handle sector, requires strategic marketing approaches that resonate with diverse international markets. Recent industry reports indicate that the global market for spring loaded handles is projected to witness a significant CAGR of approximately 5.2% from 2023 to 2030, fueled by demand in both consumer goods and industrial applications. To capitalize on this growth, manufacturers must adopt innovative marketing strategies that highlight the superior quality and functionality of their products.

Leveraging digital marketing platforms is essential in promoting these quality spring loaded handles. Companies can utilize social media campaigns and targeted content marketing to educate potential customers about the durability and efficiency of their products. It's also crucial to engage in partnerships with distributors and retailers in key markets, allowing for broader visibility and access to diverse consumer bases. As highlighted in consumer behavior analyses, 78% of customers are more likely to purchase from brands that emphasize quality and reliability in their messaging. By effectively conveying these attributes, manufacturers can not only enhance their global brand presence but also align their offerings with the evolving demands of the market.