Leave Your Message

Choosing the right Corner Metal Brackets is essential for any project. These brackets provide support and stability in various applications. Whether you're working on furniture, shelving, or structural supports, the right choice can greatly affect durability.

It’s easy to overlook details, but small decisions matter. Consider the material and weight capacity. Are you using them for heavy items or light shelves? Pay attention to size and design too. Aesthetic appeal can enhance your project’s overall look.

Making a thoughtful choice about Corner Metal Brackets often involves trial and error. You might find the perfect brackets only to realize they don't fit as expected. It’s important to measure accurately before buying. Reflect on the functionality as much as the style.

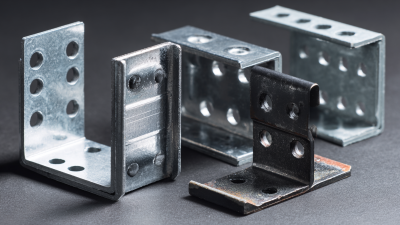

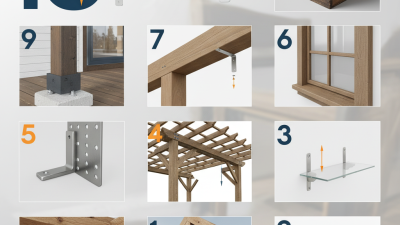

Corner metal brackets are essential in many projects. They come in various types, including L-shaped, T-shaped, and angle brackets. Each type serves a unique purpose. For example, L-shaped brackets are most common for joining two pieces at a right angle. T-shaped brackets offer extra support across larger spans.

When selecting corner metal brackets, consider the project requirements. Ensure the size of the bracket matches the materials used. Pay attention to the weight capacity, too. It is crucial to avoid underestimating the load. This mistake can lead to project failure. A tip: opt for heavier brackets for more robust structures.

Many users overlook the finish of the brackets. A galvanized or powder-coated finish can resist rust. This choice can extend the life of your projects. Don’t forget about the installation process. Sometimes, brackets can be tricky to position. You may need extra hands or tools. Remember to double-check alignment before fastening. Small oversights can lead to major issues later.

Choosing the right corner metal brackets for your projects can be challenging. Start by considering the material. Steel offers strength but may rust. Aluminum is lightweight but less robust. Think about the specific needs of your project. A heavier load requires a sturdier bracket.

Next, focus on the size. Measure your corners accurately to avoid mismatches. Incorrect dimensions can lead to instability. Consider the design as well. Some brackets come with unique shapes. This can add aesthetic appeal without sacrificing functionality.

Don't overlook the finish. A smooth finish can prevent scratches, while a rough one may offer better grip. Reflect on your project’s environment too. Outdoor projects need weather-resistant brackets. Indoor use might not require such durability, but still, think about the style. Sometimes, a perfect choice may look appealing but lacks strength. Make sure your selection balances form and function.

When selecting corner metal brackets, assessing load capacity and durability is crucial. Load capacity refers to the maximum weight a bracket can support without failure. According to industry data, brackets can typically support anywhere from 100 to 700 pounds. However, this varies based on materials and design. Always check specifications to ensure reliability.

Tips for assessing load capacity include conducting a thorough weight analysis of your project. Know the weight of shelves, cabinets, or equipment that will rest on the brackets. Also, consider dynamic loads versus static loads. Dynamic loads can add stress, so plan accordingly.

Durability is influenced by material choice and environmental factors. Stainless steel offers high corrosion resistance, while galvanized steel can protect against rust. However, proper installation is essential. A poorly installed bracket can fail, regardless of its rated load capacity. Reflect on any external forces it might face, like moisture or temperature changes. This ensures longevity in your projects.

When selecting corner metal brackets, the material is a key consideration. Steel brackets are known for their strength. They can support heavy loads and resist bending. However, they can be prone to rust if not treated properly. This is a critical factor if your project is in a humid environment. Weigh these pros and cons carefully, especially if long-term durability is vital.

Aluminum brackets are a lighter option. They offer decent strength while resisting corrosion. This makes them suitable for outdoor projects. However, you might notice they can bend under excessive weight. This limitation could affect your design choices. Plastic brackets are another alternative. They are resistant to moisture and lightweight. But they usually cannot support significant loads. They work well in applications where strength is less critical.

Choosing the right material requires a balance of strength and application. Reflecting on these choices can help avoid future headaches. Evaluating the specific needs of your project can also inform your decision. Remember, even a small oversight can lead to larger issues down the road.

| Material | Weight (per bracket) | Load Capacity | Corrosion Resistance | Cost (per unit) | Applications |

|---|---|---|---|---|---|

| Steel | 200g | 500 kg | Moderate | $2.00 | Heavy-duty applications |

| Aluminum | 150g | 300 kg | High | $3.50 | Outdoor and marine use |

| Plastic | 100g | 150 kg | Very High | $0.75 | Lightweight projects |

When installing corner metal brackets, preparation is key. Start by gathering your tools: a drill, screws, and a level. Measure the area accurately. This ensures the brackets align perfectly. A miscalculation can lead to a crooked structure. Frustrating, isn't it?

Next, mark the spots where you will attach the brackets. Use a pencil for precision. If the surface is uneven, consider using shims. They can help with leveling. Not everyone thinks about this, but it makes a significant difference.

Lastly, adhere to the weight limits. Overloading brackets can cause damage. Check the materials you are working with. If in doubt, reinforce with additional support. Learning from past mistakes is crucial. Each project brings lessons.