Leave Your Message

In the world of construction and DIY home improvement, stability and support are paramount, particularly in structural applications. Corner braces, essential components in ensuring the integrity of frames, shelves, and various constructions, have garnered significant attention from both professionals and enthusiasts alike. According to a recent industry report by the Building Components Association, the global market for corner braces is projected to grow by 15% annually through 2025, reflecting their critical role in enhancing structural resilience.

Expert engineer John Smith, recognized for his extensive work on structural stability, emphasizes the importance of choosing the right corner braces: "The right corner braces not only improve the strength of a structure but also enhance safety and durability." This highlights the necessity for consumers and builders to understand the products that offer the best support and longevity.

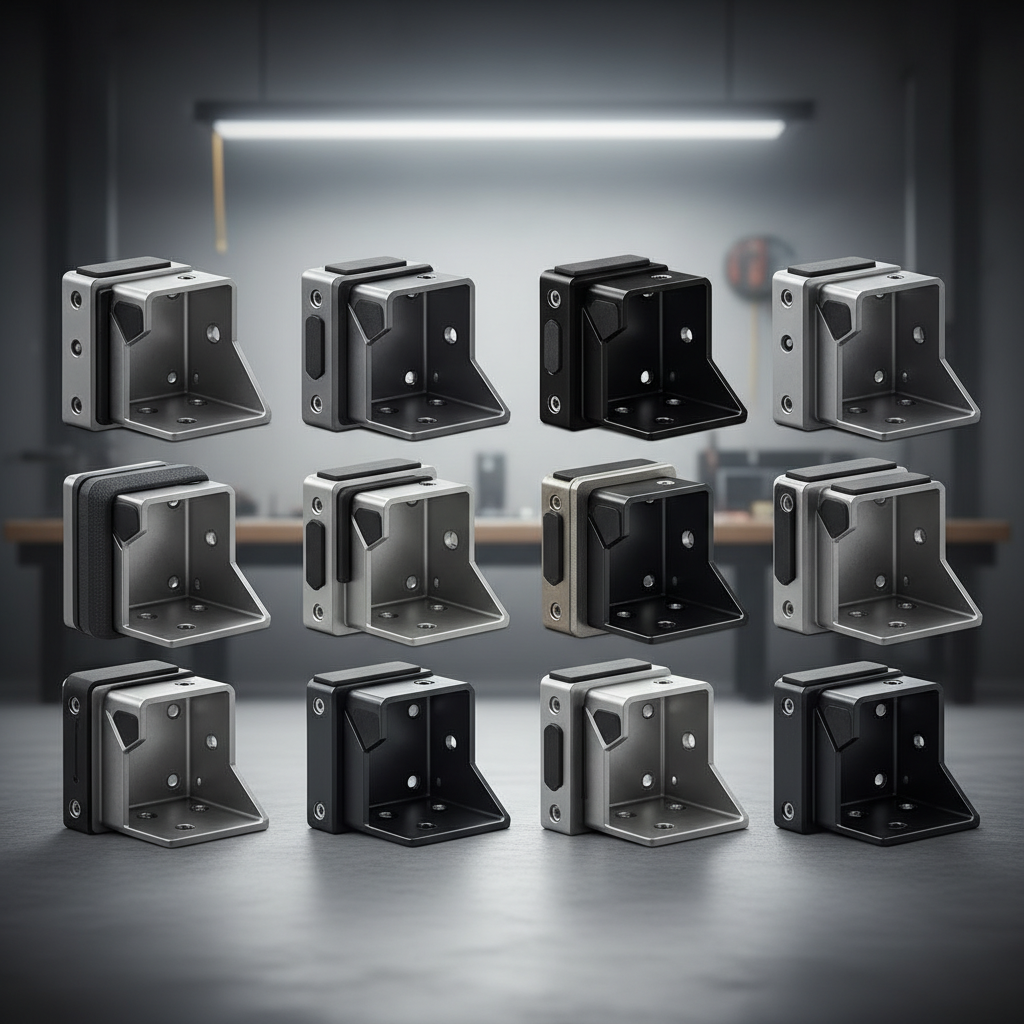

As we embark on a journey to explore the top 10 corner braces for 2025, we aim to provide insights into their features, advantages, and applications, empowering you to make informed decisions for all your construction needs. Whether you're assembling furniture, securing shelving units, or engaging in larger-scale projects, selecting high-quality corner braces is vital to achieving the ultimate stability and support.

In 2025, the emphasis on structural integrity has led to the development of innovative corner braces designed to enhance stability in various applications. Corner braces play a crucial role in construction and furniture design by reinforcing joints, ensuring that structures can withstand the forces and stresses they encounter over time. With advancements in materials and engineering, the top ten corner braces of 2025 are poised to set new standards in durability and performance.

These corner braces not only provide superior strength but also boast designs that cater to aesthetic considerations, making them suitable for both industrial and residential projects. Features such as corrosion resistance and ease of installation further enhance their appeal, allowing for quick assembly without compromising on reliability. As homeowners and builders alike prioritize longevity and robustness, the selected corner braces for 2025 promise to deliver enhanced structural integrity, ensuring that both new constructions and renovations stand the test of time.

When selecting corner braces for optimal stability, several key features should be prioritized to enhance the structural integrity of your projects. The material used in braces significantly affects performance; options like steel or aluminum provide the strength necessary to withstand substantial loads. According to industry reports, corner braces constructed from high-strength materials can improve the load-bearing capacity by up to 50%, making them an essential choice for heavy-duty applications.

Moreover, the design of the corner brace is crucial. Features such as adjustable angles and easy installation not only expedite the assembly process but also ensure precise alignment. A recent study revealed that using well-designed corner braces can reduce joint weakness by approximately 30%, leading to longer-lasting constructions. Investing in corner braces with these attributes is key for both professional woodworkers and hobbyists aiming for lasting stability in their woodworking endeavors.

The following bar chart illustrates the top 10 corner braces ranked by their load-bearing capacity (in pounds). When selecting corner braces, consider these key features for optimal stability and support.

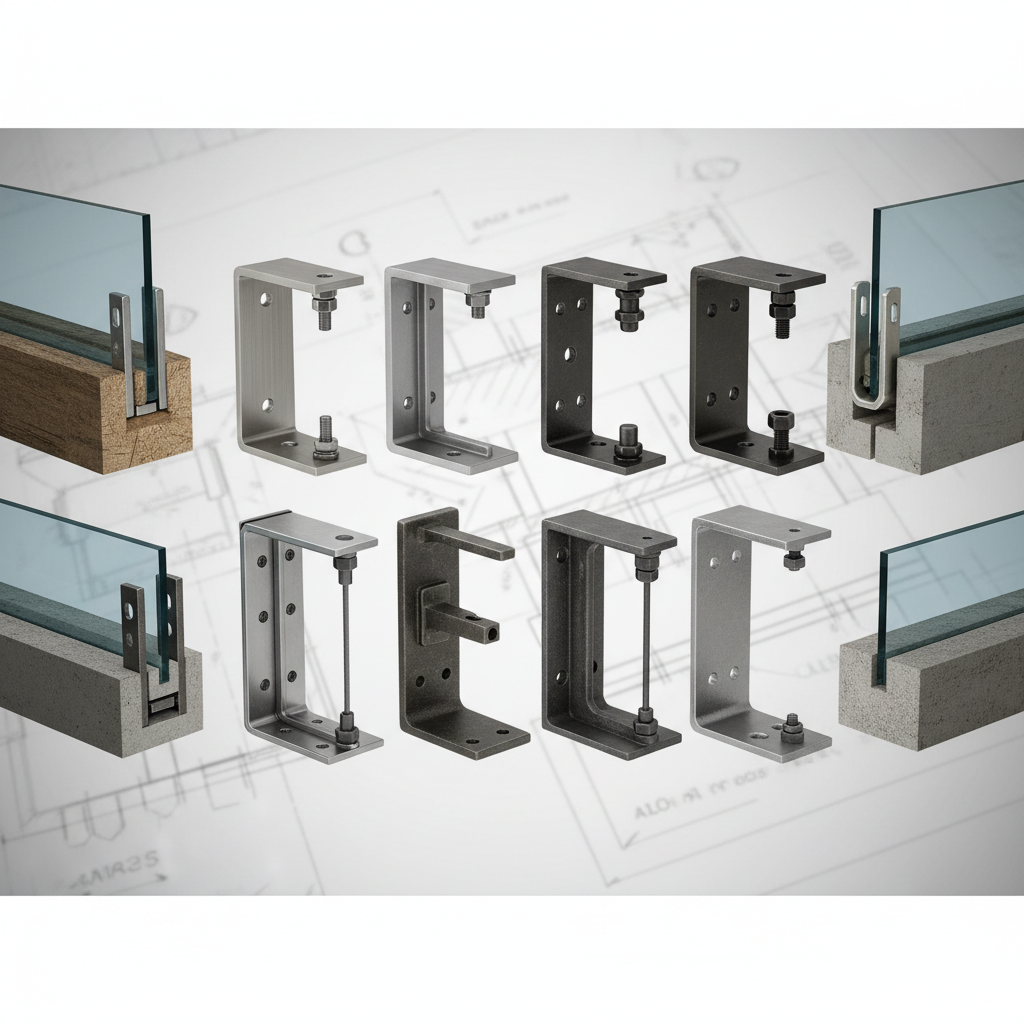

In 2025, the demand for corner braces has surged as more DIY enthusiasts and contractors seek reliable solutions for enhancing structural integrity. A comparative analysis of material strength indicates that steel and aluminum remain at the forefront for their durability and weight-to-strength ratios. According to the 2023 Structural Components Report, stainless steel corner braces exhibit a tensile strength of approximately 580 MPa, making them ideal for heavy-load applications. Meanwhile, aluminum braces, which have a tensile strength of around 310 MPa, are increasingly favored for lightweight designs without sacrificing performance.

Furthermore, advancements in composite materials are opening new avenues for corner brace applications. Recent studies, such as the 2024 Material Engineering Review, highlighted composites boasting a strength-to-weight ratio exceeding that of traditional metals. These materials are not only resistant to corrosion but also offer enhanced flexibility, which is crucial in dynamic environments. As the industry evolves, understanding the nuances of these materials is essential for selecting the appropriate corner braces that ensure ultimate stability and support for various construction projects.

When installing corner braces, proper placement and technique are crucial for achieving maximum stability and support. Begin by selecting the right corner brace for your project, ensuring it fits the dimensions of the material being supported. For instance, larger braces provide more stability in heavy-duty applications, while smaller ones may suffice for lightweight projects. When positioning the braces, aim to attach them at a 90-degree angle to the surface, allowing for even weight distribution. Use a level to ensure that alignment is accurate, preventing any potential tilting or shifting.

In addition to correct placement, using the appropriate fasteners is essential. For wooden structures, wood screws are ideal, providing strong grip and preventing the brace from loosening over time. If working with metal or other hard materials, consider using bolts and anchors for a secure fit. Always drill pilot holes first to avoid splitting the material. Lastly, check the braces periodically after installation to address any signs of wear or loosening, ensuring your projects remain sturdy over time.

Maintaining structural integrity is crucial in construction, particularly when it comes to the use of corner braces. Regular inspection and maintenance of these braces can significantly enhance stability and support. According to recent industry reports, the effectiveness of bracing systems can be compromised by environmental factors, wear, and tear. Consequently, a comprehensive inspection schedule should be implemented, ideally every six months or following any extreme weather events. This routine ensures that any signs of rust, loose connections, or deformation are promptly addressed, thereby extending the lifespan of the corner braces.

Furthermore, adherence to updated safety standards for scaffolding is essential. Recent guidelines emphasize the importance of proper tie spacing and bracing patterns to prevent failures. For instance, a study highlighted that inadequate bracing can lead to a 30% increase in accident rates on construction sites. Ensuring that corner braces are correctly installed and regularly checked in accordance with these standards is not only critical for compliance but also for protecting worker safety. Thus, contractors must prioritize ongoing training and education regarding best practices for bracing systems to promote a safer working environment in the construction industry.