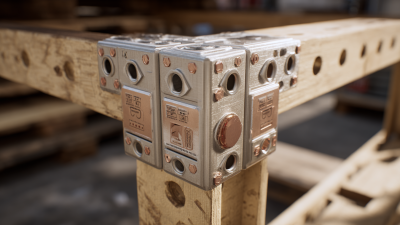

When incorporating corner braces into your woodworking or construction projects, proper installation is essential for maximizing their strength and durability. A report by the Woodworking Machinery Industry Association indicates that adequately installed braces can increase joint strength by up to 50%, reducing the likelihood of structural failure. This highlights the importance of using the right screws and ensuring that they are driven at the correct angle. Typically, screws should penetrate deep into the wood to form a tight grip, mitigating any potential wobble in the frame.

Moreover, it is recommended to pre-drill holes for screws, especially in hardwood materials, to prevent splintering and to maintain the integrity of the brace. According to the American Wood Council, pre-drilling can enhance screw holding capacity by approximately 20%, ensuring that the corner brace functions optimally. Furthermore, using high-quality materials for corner braces, such as stainless steel or heavy-duty galvanization, will significantly prolong the lifespan of your projects, accommodating for stress and wear over time. Implementing these installation tips will ensure your projects remain robust and aesthetically pleasing.