Leave Your Message

When embarking on home projects, selecting the right materials is crucial. One essential item is the Flat Corner Brace. These braces provide stability and support for various constructions. They are commonly used in furniture assembly, shelving, and framing projects.

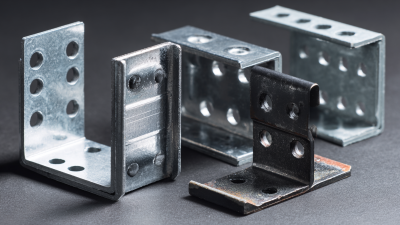

Flat Corner Braces come in different types, each suited for specific applications. Some are made from steel, while others use aluminum or plastic. Choosing the right material impacts durability and aesthetic appeal. You might prefer a sleek aluminum brace for a modern look or a robust steel brace for heavy loads.

However, finding the best flat corner brace can be a challenge. Not every project requires the same brace type. Sometimes, you may find that a brace does not fit well or offers insufficient support. This can lead to rethink your approach and reconsider your options. Exploring different styles and materials can help refine your choices. Let's dive into the top 10 flat corner brace types, ensuring you make informed decisions for your next home project.

When embarking on home projects, strength and stability are crucial.

Flat corner braces provide essential support in various applications, from furniture making to structural reinforcements. These braces come in different shapes, sizes, and materials, each offering unique benefits. For instance, metal braces are often chosen for their durability, while wooden ones can blend seamlessly into home decor.

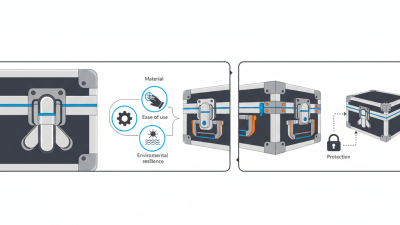

Choosing the right flat corner brace can be challenging. You might find one that seems perfect but lacks the load capacity needed for your project. Pay attention to the weight your structure will bear. Consider the joint's angle because a poor fit can compromise the stability. Some designs may even slip out of alignment, leading to potential failure. Always double-check your measurements.

Installation is equally important. A well-installed brace can prevent wobbling and extend the life of your project. However, if not applied correctly, they can warp or create stress points. It is crucial to think about the long-term implications of your choices. Sometimes, opting for a less obvious solution yields greater strength. Taking the time to reflect on each decision will pay off in the end.

When selecting flat corner braces for your home projects, material composition is key. Steel, aluminum, and plastic each offer unique benefits. Steel braces are incredibly strong, making them ideal for heavy-duty tasks. They can support significant weight. However, they are prone to rust if not coated properly. This could lead to structural issues over time.

Aluminum braces are lightweight and resistant to corrosion. They are perfect for indoor use or areas with high moisture. Yet, they might not support as much weight as steel counterparts. Consider how you plan to use them. For lighter home projects, aluminum can be a great choice.

Plastic braces are often overlooked. While they are not as strong as metal options, they are ideal for small, decorative projects. They are lightweight and easy to install. However, their durability may not match that of steel or aluminum.

Tips: Always check the weight limits before purchasing braces. Consider the environment where you’ll use them. A humidity-prone area might benefit from aluminum. Remember, choosing the right brace can affect your entire project. Don’t rush this decision. Reflect on your specific needs and project requirements.

When choosing corner braces for home improvement, understanding load capacity is crucial. Different corner brace types have various weight limits. According to industry reports, metal braces typically support more weight than plastic ones. A standard metal corner brace can withstand up to 150 pounds. On the other hand, a plastic brace may only hold about 50 pounds.

Homeowners often underestimate the load capacity needed for their projects. For example, mounting a heavy shelf requires a sturdy brace. Many think that any corner brace will suffice, but that can lead to failures. If you’re unsure, it might be wise to use a higher-rated brace than you think you need. This gives you an extra margin for safety.

People sometimes overlook the importance of installation. Properly securing the braces is just as crucial as their type. Misalignment or improper screws can reduce their effectiveness significantly. A well-chosen brace with poor installation may fail to hold even half the expected weight. It's a common mistake that can easily be avoided with careful planning.

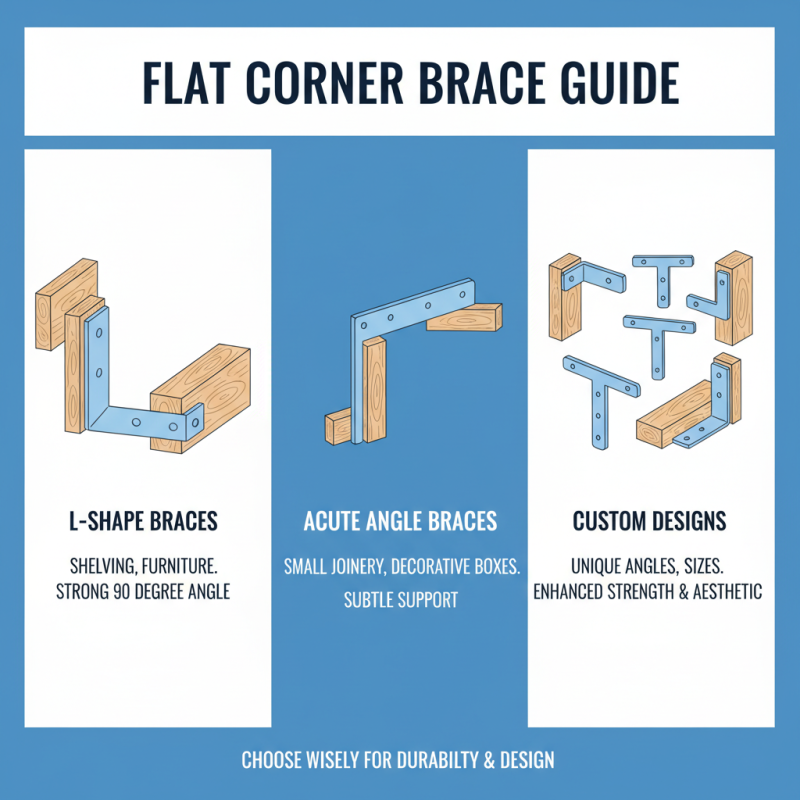

Choosing the right flat corner brace can significantly affect your home projects. Various designs offer unique angles and sizes. For instance, some braces come in L-shapes, perfect for shelving. Others feature a more acute angle, suitable for smaller joinery tasks. These variations can enhance not just strength but also the aesthetic appeal.

Exploring size options is essential. A smaller brace might suffice for lightweight items, while a larger one is better for heavy-duty applications. When selecting a brace, consider its material. Some are made from durable metal, while others are crafted from sturdy plastic. Each material has different strengths and weaknesses. Sometimes, the design might not fit well with your project’s style.

In the end, the right choice often comes with trial and error. There may be instances where the brace doesn't align perfectly. This misalignment can be frustrating but can lead to creative solutions. Keeping an open mind during your selection process can empower you to make the best choice for your projects.

When tackling home projects, installing corner braces securely is essential. Using the right techniques can enhance stability. Begin by selecting the appropriate brace type based on your project needs. Metal braces are strong, while wood options offer aesthetic appeal. Measure your corners carefully. Entering inaccurate distances can lead to uneven mounts.

Consider pre-drilling holes for screws. This minimizes wood splitting and ensures a tight fit. Use a level to check alignment. An unaligned brace can compromise the entire structure. As you install, apply consistent pressure. Uneven pressure can lead to loose screws over time.

Tips: Always use corrosion-resistant screws for outdoor projects. This will enhance durability. If you're unsure about placement, seek a second opinion. Sometimes, a fresh set of eyes can spot errors. After installation, check the braces after a few days. Tightening loose screws early can prevent larger issues later.