Leave Your Message

Strut hinges have emerged as pivotal components in modern engineering, offering unparalleled versatility across various applications ranging from aerospace to automotive manufacturing. According to a recent report by MarketsandMarkets, the global market for hinges is projected to reach USD 2.8 billion by 2026, driven by increasing demand for lightweight and robust materials. Strut hinges stand out due to their ability to facilitate smooth motion while providing significant support, making them essential for applications such as foldable structures, automated machinery, and innovative vehicle designs. Their unique design incorporates elements that allow for both vertical and horizontal movement, enhancing functionality without compromising structural integrity. As industries continue to evolve with sophisticated engineering requirements, understanding the multifaceted benefits of strut hinges becomes crucial for leveraging their capabilities to optimize performance and efficiency in engineering designs.

Strut hinges have increasingly become a cornerstone in various engineering applications due to their adaptability and robust performance. In the aerospace industry, for instance, strut hinges are essential in the design of wing flaps and control surfaces. Their ability to provide precise motion and support under aerodynamic loads allows engineers to optimize aircraft performance while ensuring safety and stability during flight. Furthermore, these hinges are lightweight yet strong, which is critical in enhancing fuel efficiency and overall aircraft design.

In the realm of automotive engineering, strut hinges facilitate the seamless operation of hoods, doors, and tailgates. They offer flexibility in design, allowing manufacturers to create innovative, space-efficient components that enhance user accessibility and vehicle aesthetics. The durability and resistance to various environmental factors also contribute to longer-lasting automotive parts. Additionally, in industrial machinery, strut hinges are utilized in equipment that requires frequent adjustments or repositioning, such as conveyor systems and automated assembly lines, proving their versatility across engineering disciplines.

Strut hinges have rapidly gained recognition in modern engineering due to their ability to enhance structural integrity while offering unparalleled flexibility. These hinges provide a robust connection point in various applications, allowing for both movement and stability. According to a 2023 report from the International Journal of Structural Engineering, the utilization of strut hinges can improve a structure's load distribution by up to 20%, significantly contributing to overall safety and performance. This is particularly crucial in industries like aerospace and automotive, where lightweight and durable components are paramount.

Moreover, the design versatility of strut hinges enables engineers to integrate them into a wide range of applications, from folding mechanisms in furniture to dynamic structures in bridges. A report from the Global Engineering Insights indicates that using strut hinges has led to a 15% reduction in material costs while maintaining the same strength specifications. This adaptability not only fosters innovation but also provides significant economic benefits, driving further interest in their implementation across various engineering disciplines.

Strut hinges play a vital role in enhancing the efficiency and performance of various modern mechanical systems. Their design allows for precise control of angular movements, providing smoother operation in applications ranging from agricultural machinery to automotive engineering. The implementation of strut hinges can significantly reduce friction, leading to faster response times and minimized energy loss. This is crucial in high-demand settings where machinery needs to operate at peak efficiency.

Strut hinges play a vital role in enhancing the efficiency and performance of various modern mechanical systems. Their design allows for precise control of angular movements, providing smoother operation in applications ranging from agricultural machinery to automotive engineering. The implementation of strut hinges can significantly reduce friction, leading to faster response times and minimized energy loss. This is crucial in high-demand settings where machinery needs to operate at peak efficiency.

Recent advancements in engineering, including the use of innovative materials like 3D-printed structures, further augment the functionality of strut hinges. These advanced materials exhibit superior specific strength, stiffness, and energy absorption, making them ideal for applications that require durability and resilience. By integrating strut hinges with these cutting-edge materials, engineers can develop mechanisms that not only perform better under stress but also adapt to varying operational demands. This synergy between strut hinges and new materials is a testament to modern engineering's commitment to enhancing performance while ensuring reliability and efficiency.

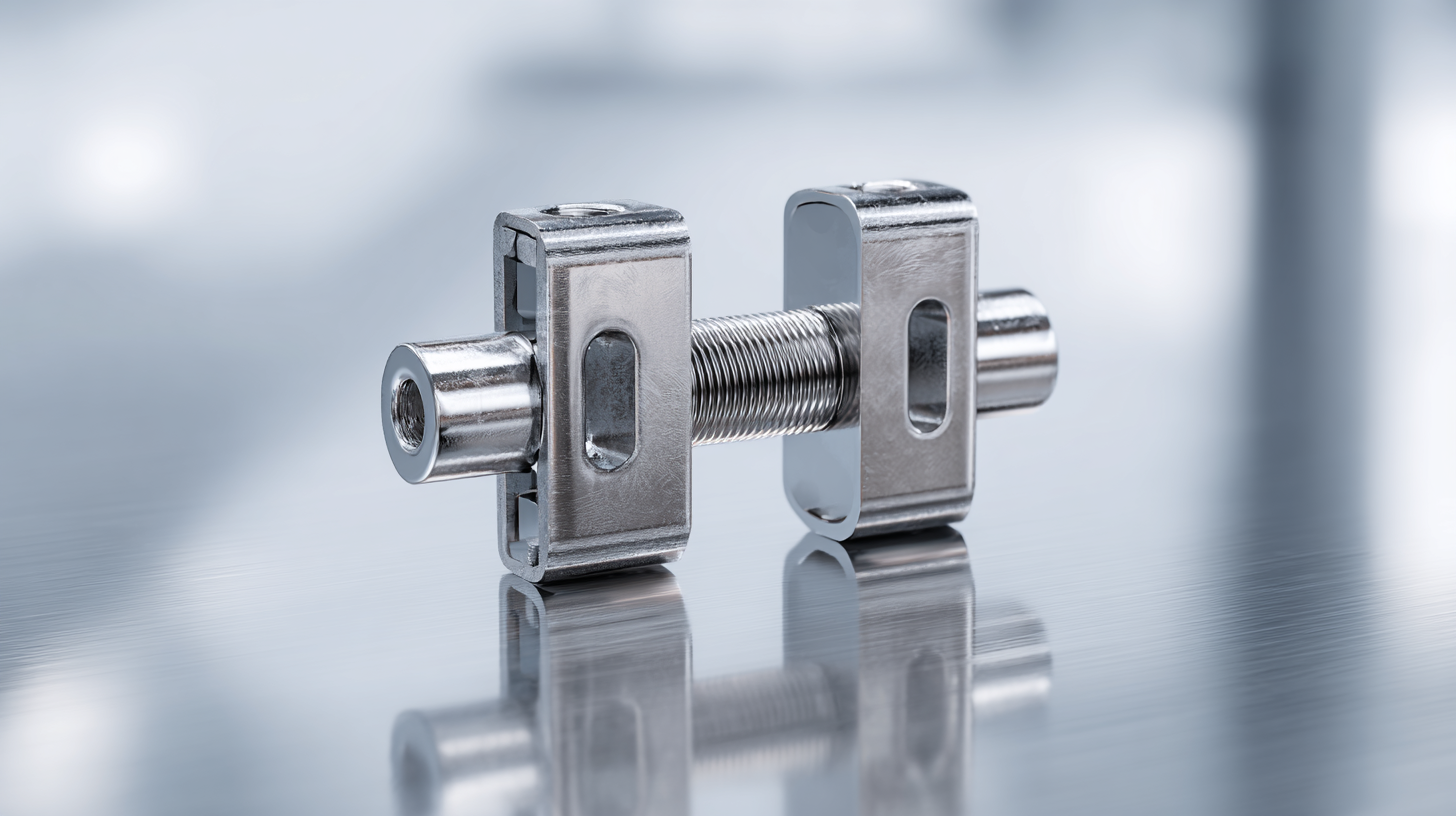

When selecting the right strut hinge for your engineering project, several key considerations come into play. First and foremost, the application’s load capacity must be assessed. According to a report by the American Institute of Steel Construction, proper load-bearing capacity is paramount, as strut hinges are often subjected to dynamic forces during operation. This means understanding both static and dynamic loads that the hinge will encounter ensures safety and longevity in performance.

Another crucial factor is the material composition of the strut hinge. As highlighted in the recent Engineering Failure Analysis report, using the right material can significantly affect corrosion resistance and temperature tolerance. For instance, stainless steel hinges are highly favored in environments exposed to moisture and high temperatures, offering durability and reliability. By evaluating these considerations alongside your project's specific requirements, you can select a strut hinge that not only meets safety standards but also enhances the overall functionality of your engineering designs.

This chart illustrates the percentage distribution of various applications for strut hinges across different industries, highlighting their versatility and importance in modern engineering projects.

Strut hinges play a crucial role in various engineering applications, particularly in the evolving realm of automated trucks, where innovative designs necessitate reliable hardware. To ensure the optimal performance of strut hinges in such demanding environments, regular maintenance is essential. Proper lubrication is one of the key maintenance tips; it reduces friction and wear, enhancing the hinge's longevity. Additionally, inspecting hinges for signs of corrosion or damage can prevent costly failures and ensure seamless operation in the demanding conditions associated with long-haul journeys.

Moreover, regular cleaning of strut hinges is vital for maintaining their functionality. Dust and debris can accumulate and impair the hinge's movement. By using appropriate cleaning methods and protective coatings, engineers can extend the life of these components significantly. As autonomous trucks become more prevalent, understanding the maintenance needs of structural hardware like strut hinges will be critical for ensuring safety and performance in the future of transportation. Implementing these practices not only fosters reliability but also supports the overall efficiency of engineering designs in modern vehicles.

| Application Area | Benefits | Maintenance Tips |

|---|---|---|

| Automotive Industry | Increased durability and flexibility | Regular lubrication and inspection |

| Aerospace Engineering | Lightweight materials enhance efficiency | Check for wear and replace as necessary |

| Construction Equipment | Robust support structure | Keep hinges free from debris |

| Furniture Design | Enhanced functionality and design flexibility | Periodic cleaning and tightening of screws |

| Industrial Machinery | High load-bearing capacity | Inspect for corrosion and replace if needed |