0102030405

Case Slide Luggage Packing Box Accessories M415

|

Place of Origin |

Guangdong ,China |

|

MOQ |

Normally 1 carton or check with the sale |

|

Samples |

Available ; Sample fee and shipping cost will be on buyer |

|

Payment Method |

Down payment and balance before shipment |

|

|

T/T ; (wire transfer) ;L/C; Western union; Moneygram ; Paypal;credit card |

|

Lead time |

1 to 3 days for in products in stock Check with the sale for those not in stock |

|

Shipping time |

Express : 3 to 10 days Air mail : 7 to 15 days( depends on areas) Train transport : 20 to 45 days(( depends on areas)) Sea shipping : 7 to 65 days (( depends on areas)) |

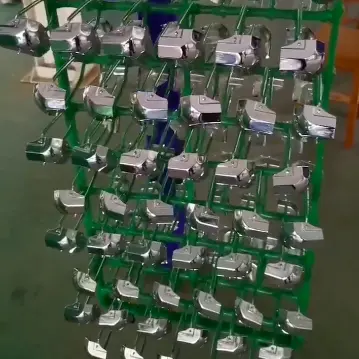

Here is a Drawbolt, which is one of the box accessories. We affectionately call it Briefcase latch, cosmetic case latch, Rolling makeup case latch, and luggage case latch. It is the largest latch in our Draw latch family, crafted from 0.05/0.6MM cold-rolled steel stamping. Not only is the material extremely economical and durable, but its surface treatment is typically accomplished through electroplating or power coating. Electroplating offers the choices of barrel plating or rack plating, with rack plating ensuring a smoother and more lustrous surface. Additionally, electroplated blue zinc and electroplated chromium are available. However, if you desire a more customized look, power coating can be employed to achieve a black, red, white, or any other color of your choosing. This accessory is commonly utilized on an array of boxes, including chest cases, decorative cases, gift boxes, suitcases, tool cases, and even small size flight cases.

The difference between rack plating and barrel plating

Rack plating and barrel plating are the most commonly used plating methods in electroplating. Do you know the differences between them? Let the rack plating equipment manufacturer tell you below.

Rack plating is suitable for products with general dimensions and is one of the most commonly used methods in electroplating production. During electroplating, the plated part is first hung on a conductive claw-shaped hanger, then immersed in the electroplating solution as a cathode, and an anode is placed at an appropriate distance on both ends. After power-on, metal ions deposit on the surface of the part.