0102030405

Die-casting latch lock M4040B-C

|

Place of Origin |

Guangdong ,China |

|

MOQ |

Normally 1 carton or check with the sale |

|

Samples |

Available ; Sample fee and shipping cost will be on buyer |

|

Payment Method |

Down payment and balance before shipment |

|

|

T/T ; (wire transfer) ;L/C; Western union; Moneygram ; Paypal;credit card |

|

Lead time |

1 to 3 days for in products in stock Check with the sale for those not in stock |

|

Shipping time |

Express : 3 to 10 days Air mail : 7 to 15 days( depends on areas) Train transport : 20 to 45 days(( depends on areas)) Sea shipping : 7 to 65 days (( depends on areas)) |

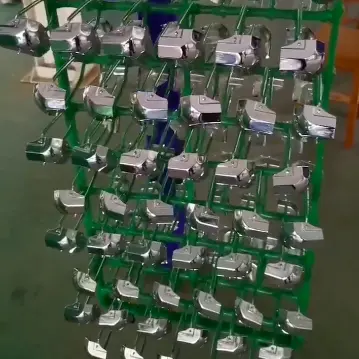

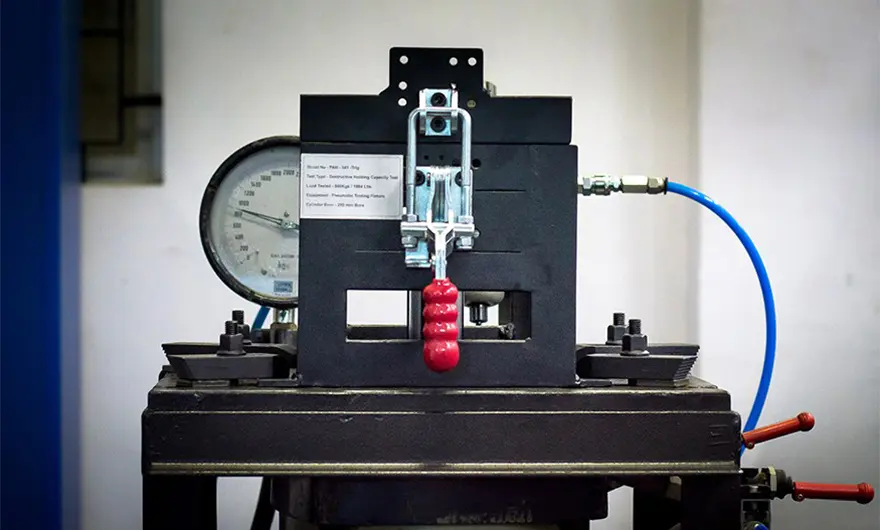

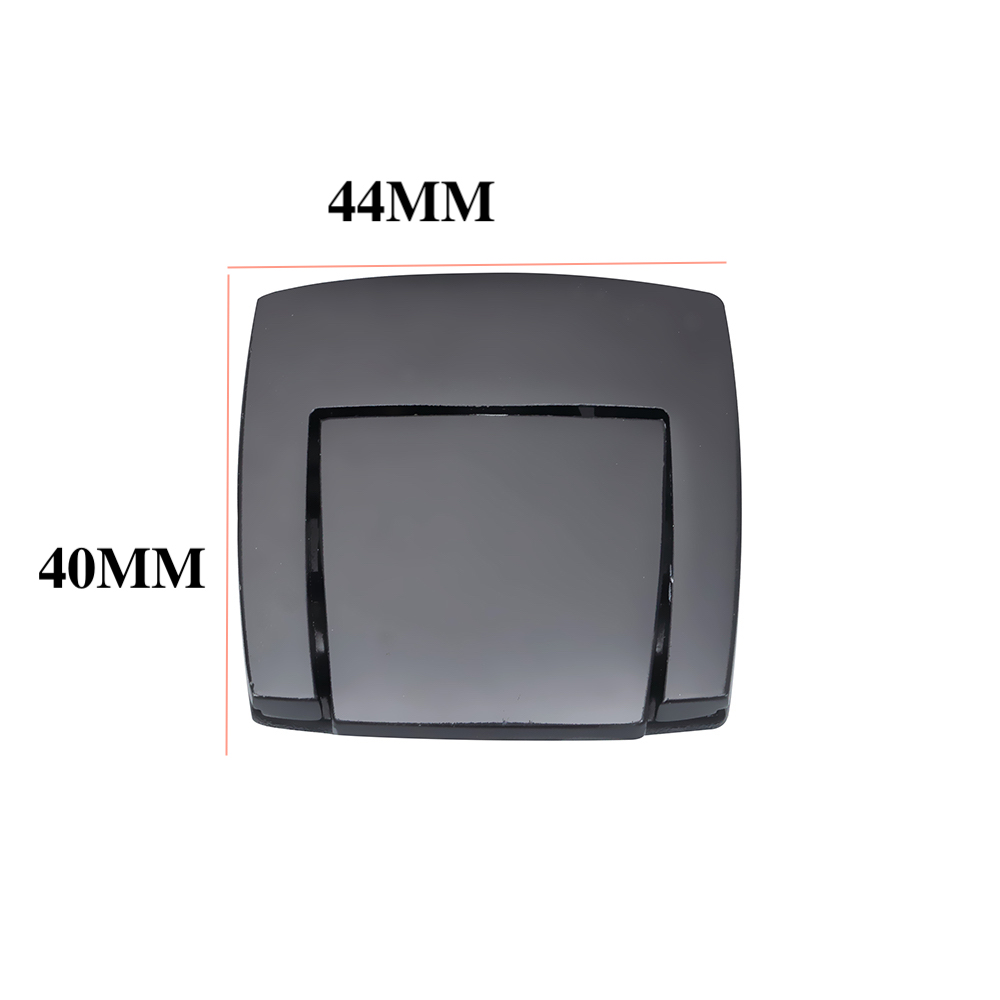

This lock is a high-quality die-cast zinc alloy lock, measuring 40*44MM in size. It is crafted from soft and ductile zinc alloy, ensuring durability and reliability. The design of this lock differs somewhat from our M4040A model, hence the installation process is also distinct. We kindly request our customers to obtain a sample for testing prior to making a purchase. This die-cast lock finds extensive application in various domains, including outdoor furniture, camping equipment, sports equipment, locking machine equipment, toolboxes, cabinets, motorcycle, and bicycle locks, among others.

The benefits of zinc die casting:

Zinc alloys possess numerous desirable attributes for the production of parts and components. Zinc is an extremely strong, rigid, and hard metal. However, through our zinc pressure die casting process, zinc can be molded into components with extremely thin walls and intricate, complex shapes. Additionally, zinc is a relatively inexpensive material.

Zinc castings:

- Possess exceptionally good electrical conductivity.

- Offer high thermal conductivity.

- Are non-sparking and non-magnetic.

- Resist corrosion.

- Are completely recyclable.

When zinc is die cast, it results in a single-piece part with no welds, bolts, or seams that could potentially compromise strength and durability. Die casting is capable of producing parts with more complex shapes, tighter tolerances, and thinner walls than other casting and molding processes.

Zinc die cast parts are utilized in a wide range of industries, including automotive and electronics.