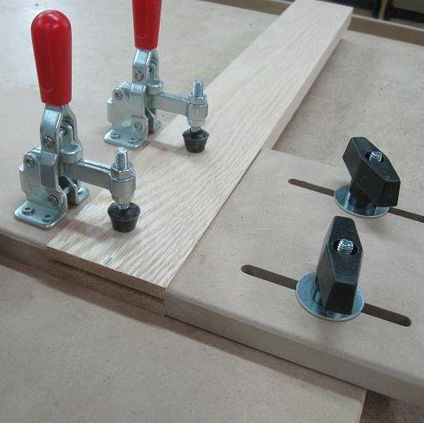

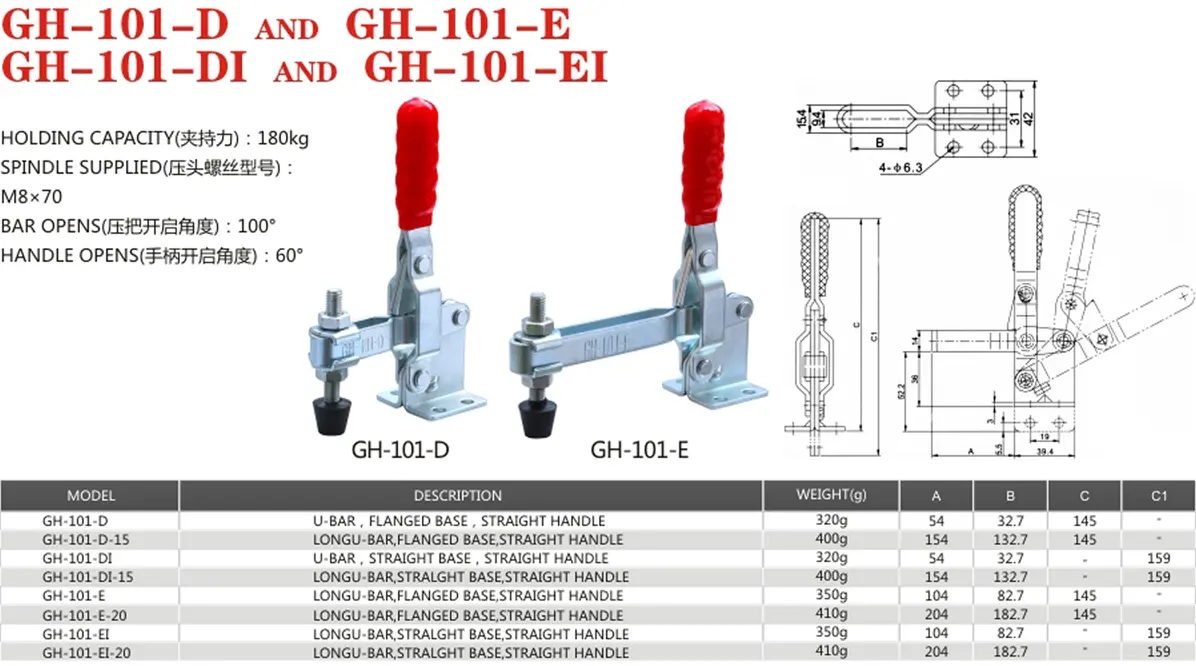

Gh-101- D Manual Vertical Toggle Clamp Flat Base Slotted Arm 700N

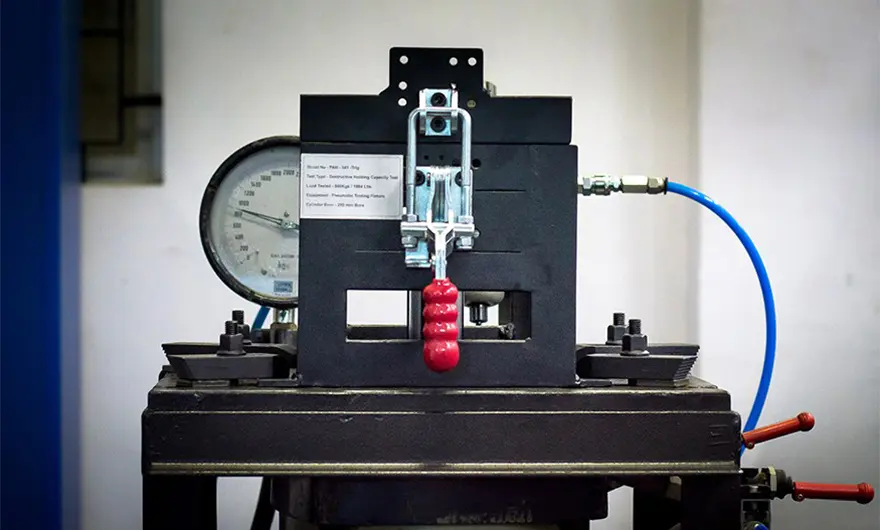

Toggle clamps know as clamping device ,fasterning tool, holding mechanism ,lever-clamp which is a versatile and useful tool that can help to improve the efficiency and accuracy of many different types of industrial and DIY projects. Our GH-101-D is a vertical toggle clamp with a holding capacity of 180Kg/396Lbs. It comes complete with adjustable rubber pressure tips for a secure grip on your work piece. Constructed from cold-rolled carbon steel with a zinc-plated coating for corrosion resistance, this clamp ensures a rock-solid hold that won't slip, making it an essential tool for any workshop

When using a toggle clamp, there are several things to keep in mind. Here are some important considerations:

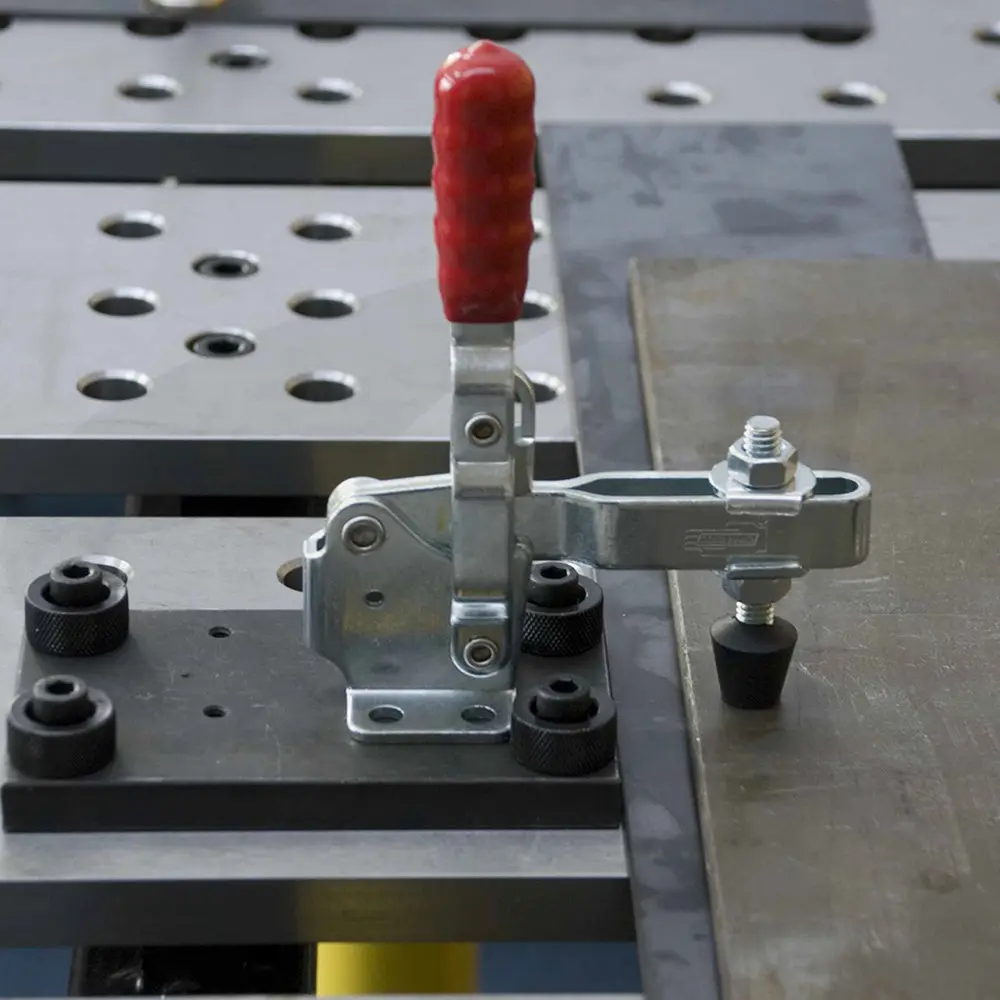

1.Load capacity: Make sure to choose a toggle clamp with a load capacity that matches the weight of the object you are clamping. Overloading the clamp can cause it to fail or become damaged.

2.Clamping force: Adjust the clamping force of the toggle clamp according to the size and shape of the object being clamped. Applying too much force can damage the object, while too little force may not hold it securely.

3.Mounting surface: Ensure that the mounting surface is clean, flat, and strong enough to support the weight of the object and the clamp.

4.Handle position: When clamping an object, position the handle of the toggle clamp in a way that allows you to apply maximum force without straining your hand or wrist.

5.Safety: Always use proper safety precautions when using a toggle clamp, such as wearing gloves and eye protection.

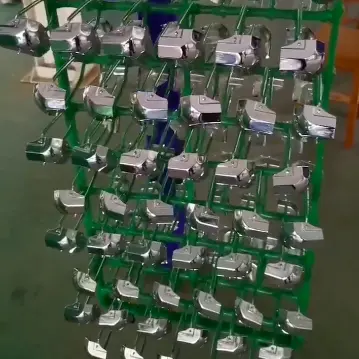

6.Regular inspection: Inspect the toggle clamp regularly for signs of wear or damage, and replace any worn or damaged parts immediately.

7.Storage: Store the toggle clamp in a dry, clean place when not in use to prevent rust and corrosion.

By following these tips, you can ensure that your toggle clamp is used safely and effectively.