Red bronze suitcase buckle lock M414B

|

Place of Origin |

Guangdong ,China |

|

MOQ |

Normally 1 carton or check with the sale |

|

Samples |

Available ; Sample fee and shipping cost will be on buyer |

|

Payment Method |

Down payment and balance before shipment |

|

|

T/T ; (wire transfer) ;L/C; Western union; Moneygram ; Paypal;credit card |

|

Lead time |

1 to 3 days for in products in stock Check with the sale for those not in stock |

|

Shipping time |

Express : 3 to 10 days Air mail : 7 to 15 days( depends on areas) Train transport : 20 to 45 days(( depends on areas)) Sea shipping : 7 to 65 days (( depends on areas)) |

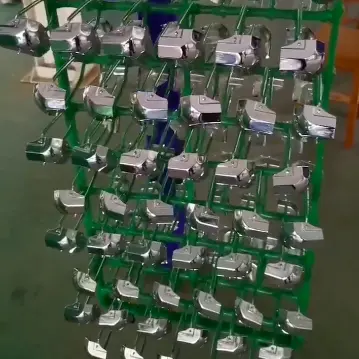

1. Surface Preparation: Before plating, the surface of the object needs to be cleaned and prepared. This may involve removing dirt, grease, rust, or other contaminants to ensure a smooth and adherent plating layer.

2. Electroplating: The object is placed in an electrolyte solution containing Red bronze ions. An electric current is applied, causing the Red bronze ions to deposit onto the surface of the object. The thickness of the plating layer can be controlled by adjusting the plating time and current density.

3. Post-Treatment: After the plating process, the object may undergo post-treatment steps such as rinsing, drying, and buffing to enhance the appearance and durability of the plating.