0102030405

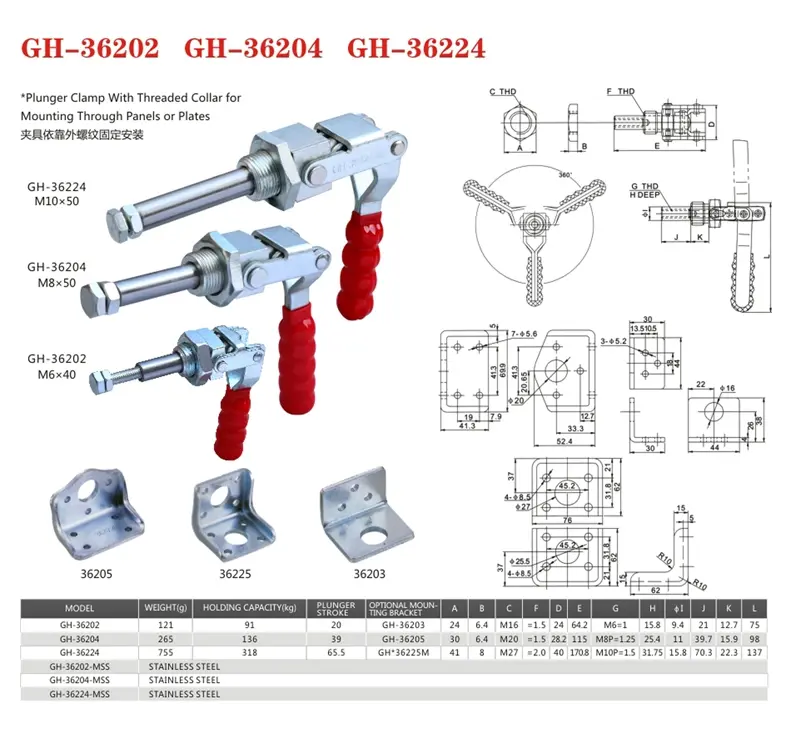

Toggle Clamp straight line action clamps with flange base CH-36092

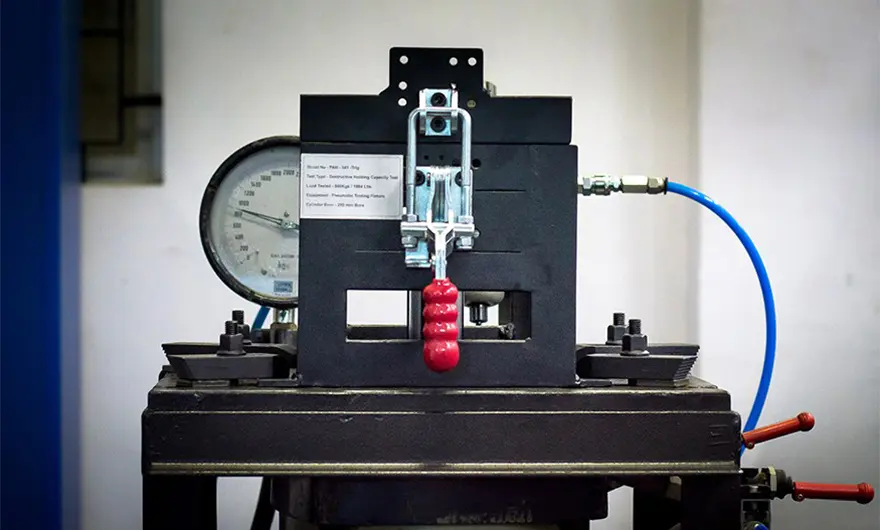

This particular toggle clamp boasts a range of names to describe its functionality and design, including straight-line action clamp, push-pull toggle clamp, push-action toggle clamp, manual toggle clamp, adjustable toggle clamp, and clamp lock. Crafted from sturdy carbon steel, this clamp is engineered for robustness and longevity in various operating conditions. To further enhance its durability and resistance to corrosion, the clamp is meticulously finished with zinc plating, which not only protects the steel from rust but also gives it a sleek appearance.

In addition to its durable construction, this toggle clamp features a vibrant red PVC coating. This coating not only serves an aesthetic purpose by adding a touch of color but also acts as a protective barrier against abrasion and external elements. The combination of materials and finishes ensures that the clamp remains reliable and performs optimally even in demanding environments.

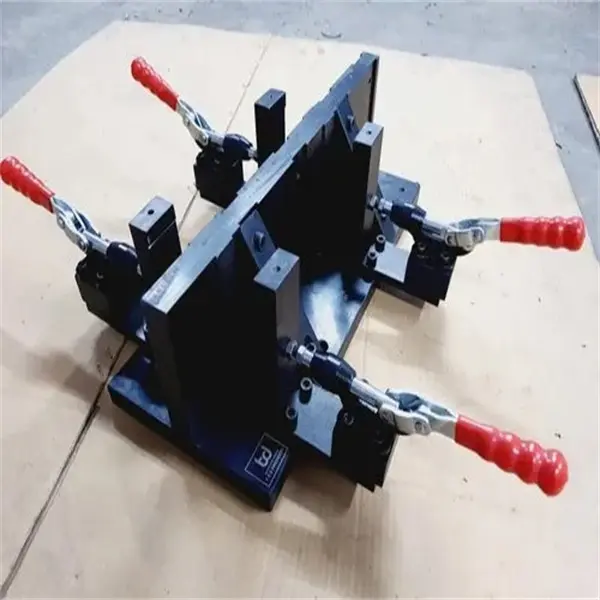

The standout feature of this toggle clamp is its straight-line action mechanism, which ensures consistent and smooth clamping operation. This mechanism is complemented by a flange base mounting, providing a stable and secure platform for attaching the clamp to various surfaces or fixtures. The flange base mounting design not only offers ease of installation but also enhances the overall stability of the clamp during use.

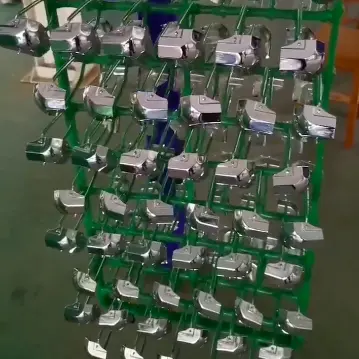

With its versatile design and robust construction, this toggle clamp is a versatile tool suitable for a wide range of applications. From woodworking and metalworking to fabrication and industrial settings, this clamp offers a reliable solution for securely holding workpieces in place during machining, assembly, or other tasks. Its combination of features makes it a valuable addition to any workshop or manufacturing environment where precision clamping is essential for successful operations.