0102030405

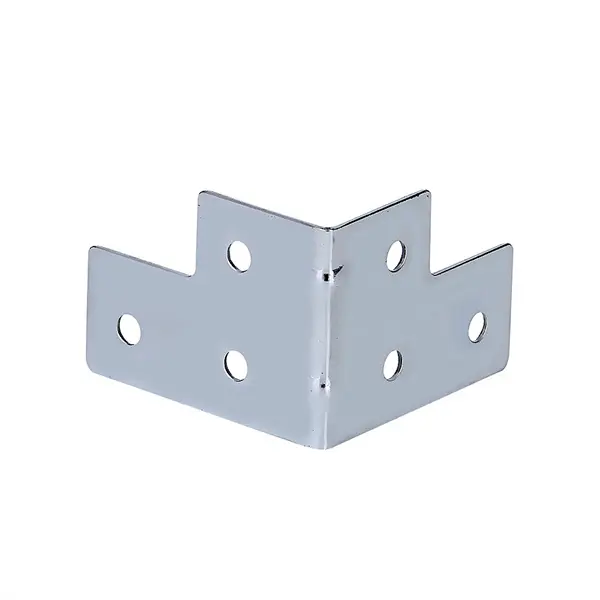

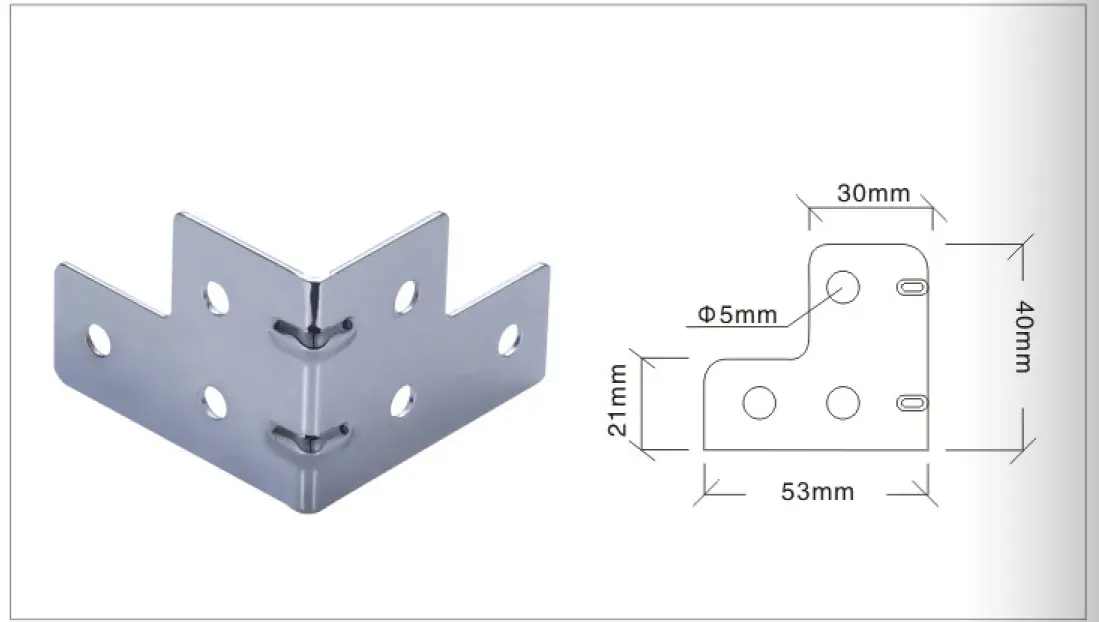

Heavy Duty Metal Corner brace with ribs MB5340A

|

Place of Origin |

Guangdong ,China |

|

MOQ |

Normally 1 carton or check with the sale |

|

Samples |

Available ; Sample fee and shipping cost will be on buyer |

|

Payment Method |

Down payment and balance before shipment |

|

|

T/T ; (wire transfer) ;L/C; Western union; Moneygram ; Paypal;credit card |

|

Lead time |

1 to 3 days for in products in stock Check with the sale for those not in stock |

|

Shipping time |

Express : 3 to 10 days Air mail : 7 to 15 days( depends on areas) Train transport : 20 to 45 days(( depends on areas)) Sea shipping : 7 to 65 days (( depends on areas)) |

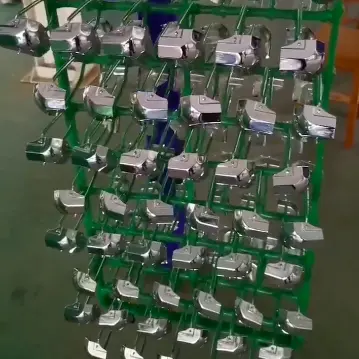

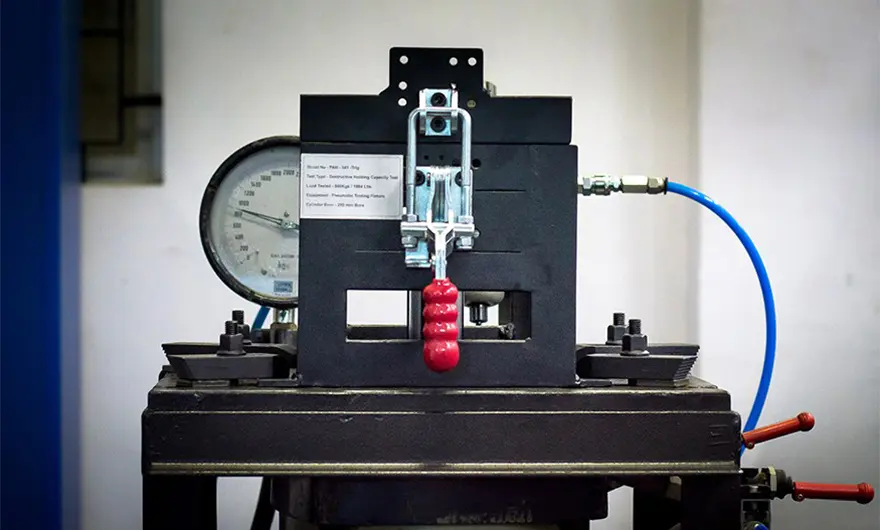

This is a Chrome Road Case L-Brace Plate, which is perfectly compatible with 30mm aluminum profiles and can be easily riveted onto them. Constructed from either 1.0mm or 1.2mm mild steel or stainless steel 304, this plate is stamped with precision by an automated machine. Once the stamping process is complete, the fittings are sent to a plating factory where they undergo chrome plating, zinc plating, or power coating, as per the customer's request. The brace boasts a precisely angled 90-degree design and features six holes with a diameter of 5.0MM, ensuring a secure and stable installation on the box.

To install a corner brace, follow these steps:

1. Prepare the installation area: Ensure the surface where the corner brace will be installed is clean, dry, and free from debris.

2. Position the corner brace: Align the brace with the corner of the structure or object where it will be attached.

3. Secure the brace: Use screws, bolts, nails, or other appropriate fasteners to attach the corner brace firmly in place. Ensure the fasteners are tightened enough to provide a secure connection.

4. Test the stability: Once the corner brace is installed, test the stability of the structure or object to ensure it is adequately supported.

5. Optional finishing touches: If desired, you can apply paint, sealant, or other finishes to the corner brace to protect it from corrosion or to match the surrounding surface.

It's important to follow the manufacturer's instructions and safety guidelines when installing a corner brace. If you're unsure or need assistance, it's recommended to consult a professional or seek expert advice.