0102030405

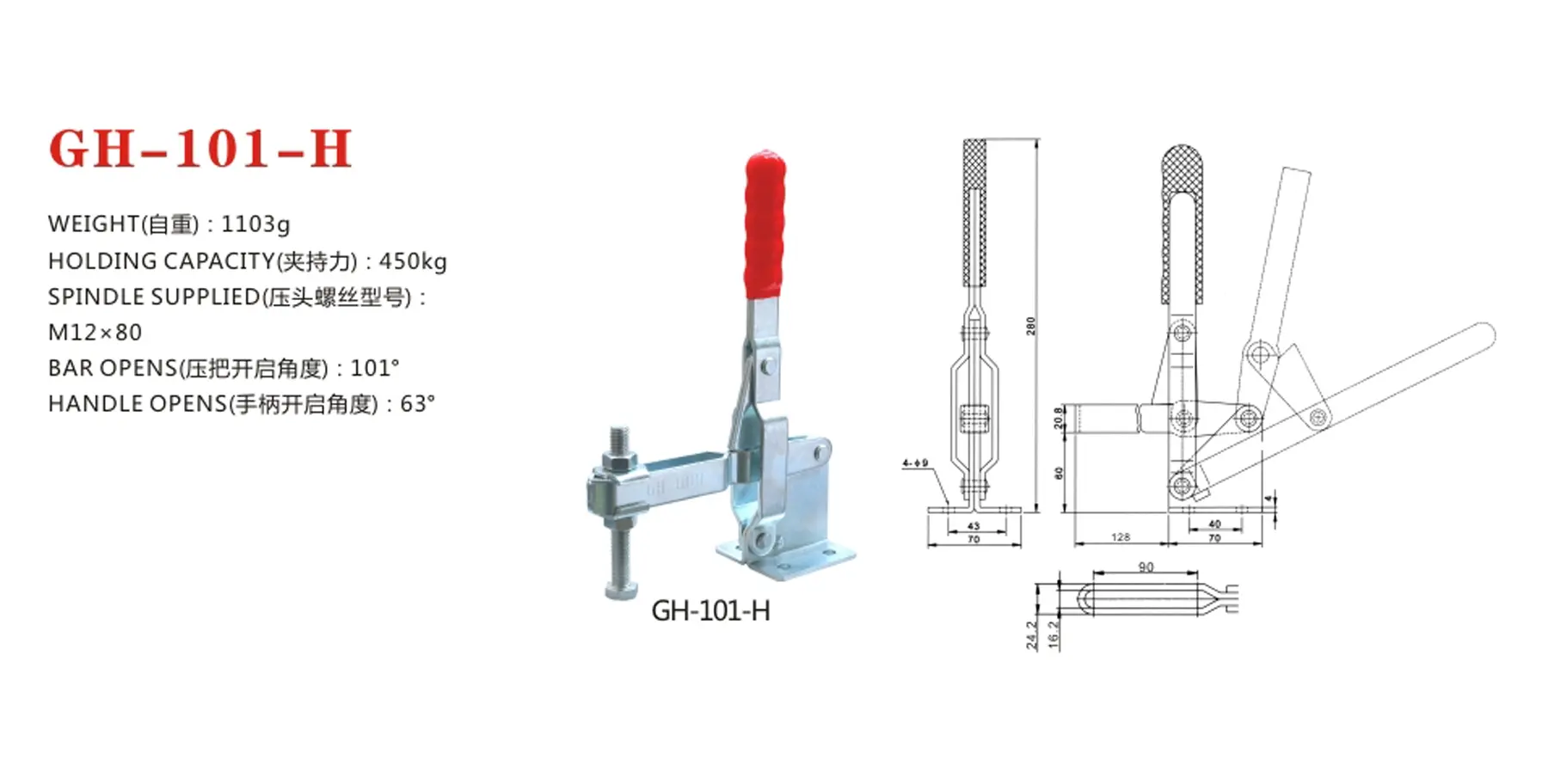

Heavy duty vertical toggle clamp GH-101-H

This vertical manual toggle clamp, model GH-101-H, exerts a clamping force of 450 kilograms. The spindle supplied is M12X8, with a bar open angle of 101° and a handle open angle of 63°. The GH-101-H comes with a long U-bar, weighing 1103 grams, providing heavy-duty loading capacity. It stands at a total height of 280mm and a total width of 207mm. The U-bar adjustment range is from 0 to 90mm, and the plunger, made of steel, has an adjustable range of 0 to 60mm.

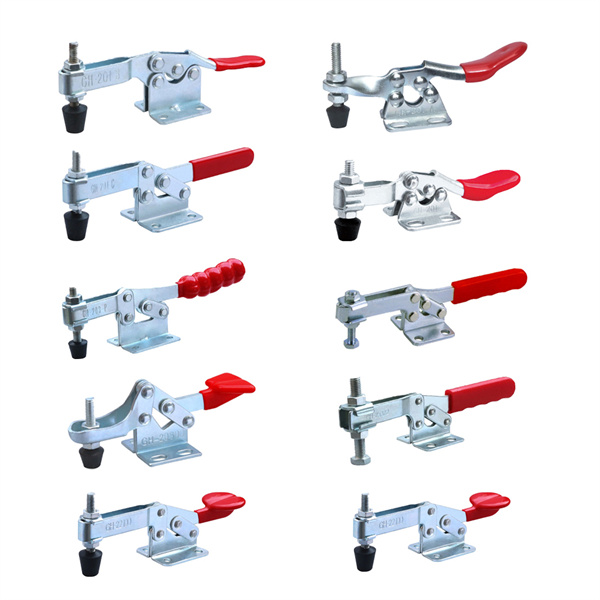

These adjustable toggle clamps are commonly used in various industries, including Automotive, Food and Packaging, Industrial, Fixturing and Testing, Welding, and Assembly.

Difference between manual toggle clamp & air-powered toggle clamp

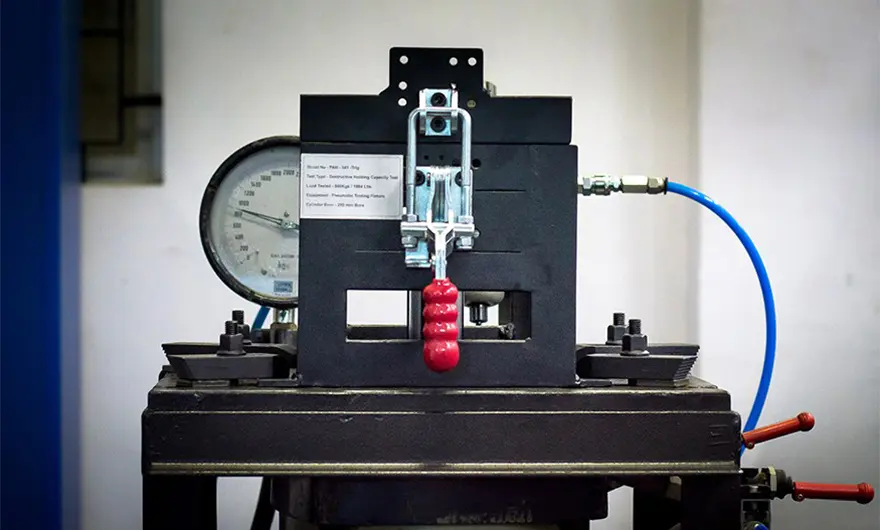

Manual toggle clamps and air-powered toggle clamps are two types of clamping mechanisms with distinct operational differences.

Manual toggle clamps, as the name suggests, are manually operated by hand. They offer a straightforward and simple operation without the need for external power sources. While manual toggle clamps are reliable and easy to use, they may not be ideal for high-speed or high-volume production environments due to their slower operation. Additionally, manual toggle clamps require physical effort from operators, which can lead to fatigue during extended use.

On the other hand, air-powered toggle clamps utilize compressed air to engage and disengage the clamping mechanism. These clamps are known for their rapid operation, making them well-suited for applications requiring high speed and efficiency, such as in automated production lines. Air-powered toggle clamps also reduce the physical strain on operators, enhancing workplace ergonomics and reducing the risk of fatigue-related issues. However, the use of air-powered toggle clamps necessitates the presence of an air compressor or pneumatic system, adding to the initial setup complexity and cost.

When choosing between manual toggle clamps and air-powered toggle clamps, it is essential to consider factors such as the required operation speed, production volume, operator comfort, and available resources. By evaluating these factors, you can select the type of toggle clamp that best suits your specific application needs and operational requirements.